Polyether Foam Fabrications

Polyether Foam Fabrications

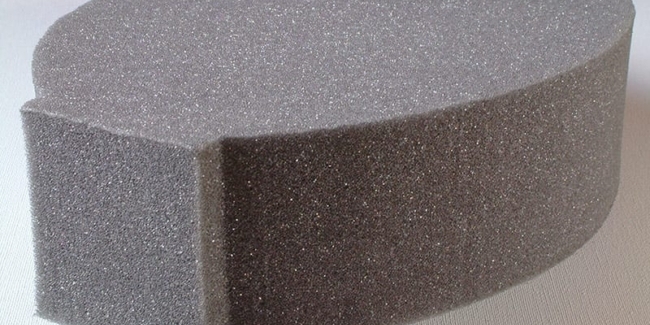

Advanced Seals & Gaskets Ltd manufacture and supply a number of fabricated components produced using Polyether Polyurethane Foams, available in a selection of densities and grades. As with other PU foam fabrications, those made from Polyether foams are suited to a wide range of applications as it’s a highly versatile material offering more resistance to oxidation and ageing in comparison to most other rubber and foams. As well as being durable and lightweight, it is also cost-efficient making it a popular choice for many items classed as ‘long-life’ such as seat cushions and sofa fillings.

Polyether Polyurethane foam is manufactured in very large master blocks or ‘buns’ usually ranging from around 2 to 2.5meters in length, , 1 to 2 metres in width and 175 to 1260 mm in thickness, which are held in stock from which we can convert into countless bespoke profiles. A Polyether Foam fabrication requires specialist machinery, usually a selection of saws, drills, buffers and knives. By choosing ASG for your fabrications, you will also benefit from the option using our CNC oscillating knife, which can automatically cut and drill fabricated parts by reading CAD drawings. Polyether Foam Fabrications are often taken as a cheaper alternative to mouldings and extrusions as there is no initial die/tooling cost for production of bespoke shapes which are usually required as 1 off prototypes or small quantity runs. All our Polyether Foam fabrications are made to order and are produced using samples or drawings provided by customers, and can take many forms for example multiple material laminating to create composite sheets which are then cut down into gaskets, washers, strip, displays & signage - such as logos/lettering and seals with flexible joints or irregular angles.

Product Enquiry

For information on Polyether Foam Fabrications please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Polyether Polyurethane Foam

- Density: 22 - 24 kg/m3

- Colour: Grey/white

- Block Size: (L) 2 to 2.5meters x (W) 1 to 2 metres x (T) 175 to 1260 mm

- Fire Resistance: (FMVSS302) Pass

- Minimum Temperature: -20°C

- Maximum Temperature: +120°C

Full technical data can be supplied upon request,

or downloaded from our online portal.

What are Polyether Foam Fabrications?

Polyurethane foams are just one of many members of the polymer family, with Polyether being a soft, open cell, low density variant, available in grey or white often used in low cost applications including those that require fabricated parts. Polyether PU foams are formulated and manufactured using a combination of polyether polyols, catalysts and blowing agents which create the foam open cell texture. During the manufacturing process, further additives can be added to the formulation in order to produce Polyether foam with additional properties such as flame retardancy, anti-static, anti-bacterial and many more. A fabrication is the procedure of turning blocks or sheets of Polyether foam into custom made 3D usable shapes. Polyether Fabrications are created using CNC machines, saws, drills, buffers etc, enabling us to create unique products that usually cannot not produced by one single process, where the item is too big to be produced in one single piece, or where 3D profiles are required such as cubes or cone shapes.

Why use Polyether Foam Fabrications?

Advanced Seals & Gaskets Ltd have a team dedicated to fabrication construction and the production of one offs and complex products to use during the design and prototype development stage or when singular items are required. Polyether PU Fabrications are often used as a cheaper alternative to mouldings and extrusions as they dont require initial expensive tooling and set up costs in order to produce the bespoke shapes. Fabrications are ideal for use as samples or prototypes for testing prior to paying for the tooling required for the bulk quantities made by moulding or extruding the material. Fabrications are also perfect for producing props, signs, displays, packaging case/box inserts with routered out shapes to hold individual items in place.

Polyether Polyurethane Foams used for these fabrications are soft, lightweight and have a low density, the materials are manufactured as large blocks of material which can be easily split, sawn and fabricated into many different components each with excellent properties including excellent compressibility, meaning it will bounce back and recover quickly, this compressibility makes it a great choice of materials of cushioning applications. It’s flexible with a high tensile properties and tear resistance, resistance to mold, mildew and fungus growth as well as grease oil water and temperature with working temperature range of around -20°C to +120°C. Polyether Polyurethane fabricated components can be found used in applications such as cushioning, sound and vibration dampening, heat insulation, packaging and surface protection.

Available Grades of Polyurethane

Advanced Seals & Gaskets Ltd work with a number of material manufacturers, giving our customers more choice when looking for polyurethane foams , our most popular grades being:

- Acoustic

- Egg box

- Pick & Pluck

- HLB

- Basotech

- Polyester

- Recon

- Retic

Benefits of Using Polyether Polyurethane Foam

- Compressibility

- Cushioning

- Light-weight

- Low thermal conductivity

- Low water vapor transmission

- Mildew-resistance

- Resiliency

- Sound absorption/Vibration dampening

Advantages of using Polyether Polyurethane Foam Fabrications

Our polyether polyurethane foams are highly durable and versatile offering a vast range of desirable attributes as well as being cost effective allowing it to be used across several industries and applications. These foams are available in grey or white colour options with excellent properties. The main advantage of Polyether Polyurethane fabricated parts is the cost saving to customers who don't have to pay for expensive tooling set ups and minimum order quantities.

Being an open cell foam, the Polyether is a breathable material meaning its allows air to circulate throughout its structure, it offers excellent compressibility, meaning it will bounce back and recover quickly from repeated loading, this compressibility makes it a great choice of materials for cushioning applications. The Polyether foam fabrications are flexible with a high tensile properties and tear resistance, resistance to mould, mildew and fungus growth as well as grease oil water and temperature with working temperature range of around -20°C to +120°C.

It’s soft composition makes it ideal for use within sportswear, medical devices and more popularly packaging. Due to the open cell structure of this particular foam, it doesn’t hold moisture, is quick drying and allows some airflow, characteristics which are suitable for the fabrications to be used in outdoor seating, filtration, speaker foams, etc. Polyether Polyurethane foam fabrications can be found used in a range of sound and vibration dampening applications, cushioning, sealing, impact or bumper pads and even seals or gaskets within aerospace, automotive, machinery and appliances manufacturing.

Please contact us using the form below or by calling us on +44(0)1384 252555.