Polypropylene Pads

One of the thousands of cut pads available from Advanced Seals & Gaskets Ltd include those made using various types of plastics, available in numerous grades, colours and thicknesses, one of which includes Polypropylene (PP).

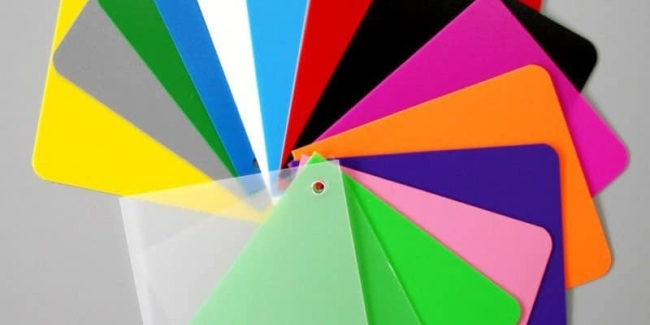

Polypropylene (PP) is one of the most commonly used thermoplastics in the world, with. Polypropylene pads used in the production of a range of packaging plastic parts for machinery and equipment. Polypropylene sheet is available in two versatile grades, PPH (Homopolymer) and PPC (Copolymer), and depending on the grade available in a choice of colours including Natural, Black, White, Beige, and sheets sizes up to 4 metres x 2 metres in size and 200mm in thickness from which pads can be cut.

Pads which require a textured finish or can not be be cut from standard sized sheets can also be made to order by being moulded. Our onsite conversion facilities allow us to machine these sheets of material into a choice of bespoke finished pads with a choice of self adhesive and foil finishes.

Product Enquiry

For information on Polypropylene Pads please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Polypropylene Plastic:

- Colours: Transparent or opaque - available in a choice of shades and colours

Texture: smooth, slippery

- Thicknesses: up to 200mm - Polypropylene Homopolymer (PPH) up to 20mm - Polypropylene Copolymer (PPC)

- Temperature Range: -20°C up to +80°C

- Resistances: Good resistance to wear, impact, chemicals, high temperature

- Flammability: highly flammable.

Full technical data can be supplied upon request,

or downloaded from our online portal.

What are Polypropylene Pads?

Gaskets are a ring, sheet or cut shape substance or material used to act as a seal between surfaces. The purposes for gaskets of this type are to prevent leakages of liquid or gas, keep joints air-tight and prevent the intrusion of damaging debris such as dust.

Acoustic foam is an open cell, lightweight, class O fire rated polyurethane material that is primarily used in soundproofing applications such as recording studios, and It is a non-fibrous foam meaning the gaskets can be used within airflow systems as the material doesn’t shred, dust or migrate when exposed to high velocity airflow.

Acoustic Foam is resistant to most fungus, mildew and bacteria growth as it contains anti-fungal agents which makes it a popular choice for use within the air conditioning and duct-work systems.

Why use Polypropylene Pads?

Class O Acoustic Foam Gaskets can be manufactured with a plain or self-adhesive backing to allow for easy installation and to hold the gasket in place, ensuring it remains stable even if the application moves.

Clients can choose from a selection of adhesives including acrylic, scrim and tissue with low, medium or high tack options, depending upon the individual requirements. Acoustic foam gaskets can also be cut from foam laminated to a range of our other materials using spray adhesives.

Other types of Plastic Pads available

There are various ways in which our customers utilize acoustic foam gaskets, these include sound absorption. Due to its excellent sound dampening properties, acoustic foam gaskets are often used for fittings within marine applications, recording studios, acoustic/compressor or generator enclosures, etc.

Many industries also utilize acoustic foam gaskets for insulation, vibration control and cushioning due to the materials exceptional fire resistance properties (Surface Spread of Flame Class 1 BS 476 part 7 and Building Regulations 1991 (fire safety) Class 0 BS 476 part 6&7).

These include heating & ventilation, construction, automotive, and electrical equipment and appliance manufacturing.

Benefits of using Polypropylene Plastics

- Can be manufactured in a range of transparent colours

- Resistant to chemicals including Diluted bases and acids

- Flame retardant

- Strong, Durable and Impact resistant

- Weather resistant

- Good machinability

- FDA approved

Advantages of using Polypropylene Pads

Pads cut from Polypropylene offer users a range of excellent properties and bring many advantages to using them. Polypropylene pads offer excellent fatigue resistance, elasticity, strength and durability making them perfect for use in a wide range of industries and applications.

Polypropylene Pads have high insulation properties making it safe for use as casings and enclosures for cables and electrical products. Polypropylene pads are so strong they can be twisted 360 degrees without snapping therefore perfect for use as hinges and parts where they will be subjected to high levels of stress and manipulation.

Polypropylene Pads are waterproof and extremely resistant to moisture absorption, which is why it can often be found used in the construction of packaging. The high resistance to chemical corrosion makes these pads a popular choice for use in equipment and machinery where cleaning products, bleaches, first-aid products and medicines are processed.

Polypropylene Pads can be manufactured in a broad spectrum of colours in a transparent or opaque finish and is a relatively cheap material to manufacture and therefore great for the production of mass-produced or disposable products.

Please contact us using the form below or by calling us on +44(0)1384 252555.