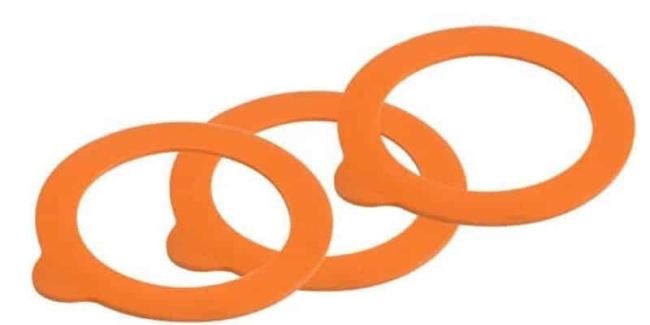

Solid Shotblast Rubber Seals

Shotblast Rubber Seals. At Advanced Seals and Gaskets, we understand the challenges posed by abrasive conditions and are proud to offer a product designed to excel in such settings. Our Shotblast Rubber Seals are engineered to provide superior protection and sealing integrity, ensuring optimal performance in shotblasting and abrasive applications.

Key Features:

- Abrasion Resistance: Our Shotblast Rubber Seals are manufactured with premium-grade rubber compounds formulated to withstand abrasion from shotblasting processes. This high abrasion resistance extends the lifespan of the seals, reducing the need for frequent replacements.

- Tight Sealing: Engineered for exceptional sealing effectiveness, our seals create a reliable barrier against abrasive particles, dust, and contaminants. This tight sealing provides an effective seal even in harsh, abrasive environments, preventing the ingress of damaging elements and contributing to equipment longevity and reduced maintenance.

- Reinforced Strength: Shotblast Rubber Seals are reinforced with additional materials to enhance structural integrity and impact resistance. High elongation at break ensures the seals maintain durability and flexibility under harsh conditions, preserving their shape and sealing performance.

- Shock Absorption: The unique composition of our seals includes shock-absorbing properties, mitigating the impact of shotblasting forces and reducing wear and tear on both the seals and the surrounding components.

- Chemical Resistance: Our Shotblast Rubber Seals exhibit remarkable resistance to a wide range of chemicals and fluids commonly encountered in industrial environments. Correct contact with chemicals and surfaces is essential for optimal sealing and wear resistance, further enhancing the durability and reliability of the seals.

- Customisation: We understand the diversity of shotblasting applications. Our Shotblast Rubber Seals can be tailored to meet specific sizes, shapes, widths, and sealing requirements, ensuring a seamless fit across various equipment and machinery.

- Easy Installation: Designed for ease of installation, our seals facilitate efficient assembly, replacement, and maintenance, minimising downtime and enhancing operational efficiency.

One of the product ranges supplied by Advanced Seals & Gaskets includes Solid Shotblast rubber seals, which is just one of thousands of products on offer. We provide the highest-quality solid shotblast rubber seals, including shotblast rubber gaskets and shotblast rubber sheeting, all manufactured in-house for quality and precision. These products are available in forms such as strips, wear strips, and for lining and chute lining applications, as well as gaskets, washers, O-rings, mouldings, and extrusions, all designed for the purpose of preventing leaks or the ingress of dust, dirt, air, fluids, and gas or for insulation and protection. Our Shotblast Rubber seals are made to order and are produced using samples or drawings provided by customers to ensure the final product perfectly fits the application and doesn’t fail. As each seal type requires a different manufacturing process, ASG has invested heavily in various machinery, enabling us to offer most seal types in both high and low quantities.

Applications:

- Shot blasting applications: Our seals, including shotblast rubber gaskets and shotblast rubber sheeting, are ideal for a wide range of shot blasting applications, providing abrasion resistance and effective sealing.

- Shotblasting Equipment: Our seals are essential components of shotblasting machinery, ensuring effective sealing against abrasive particles and contaminants during blasting.

- Mining and Construction: Shotblast Rubber Seals are used in heavy machinery in the mining and construction industries, where abrasive materials and harsh conditions are common.

- Manufacturing: These seals are valuable in manufacturing processes that involve abrasive materials or particles, such as metal fabrication and surface preparation.

- Foundries: Shotblast Rubber Seals play a crucial role in foundries, where abrasive processes are used to clean, shape, and finish metal products.

- Industrial Cleaning: Our seals are suitable for industrial cleaning equipment that employs abrasive materials to remove dirt, rust, and coatings from surfaces.

At Advanced Seals and Gaskets, we specialise in delivering sealing solutions tailored to demanding environments. Our Shotblast Rubber Seals exemplify our dedication to innovation, durability, and reliability, making them an indispensable asset for industries seeking top-tier sealing solutions for shotblasting and abrasive applications. We produce custom gaskets and sheeting in-house to meet the required specifications for each application, ensuring every product is built for performance and longevity. Choose Advanced Seals and Gaskets’ Shotblast Rubber Seals to elevate your industrial processes with seals that excel in abrasive environments and challenging conditions.

For information on Shotblast Rubber Seals, please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Enquiry

For information on Solid Shotblast Rubber Seals please complete the following quick enquiry or call us on +44(0)1384 252555.

Key Characteristics of Solid Shotblast Rubber

- Colour: Tan or black

- Shore Hardness: 45° to 50°

- Temperature: -40°C to +85°C

- Available standard manufactured sizes:

- 1mm to 6mm thick @ 1.4m x 10 meters long

- 8mm to 25mm thick @ 1.4m x 5 meters long

- 32mm, 38mm & 40mm thicknesses @ 1m x 1m sheets

What are Solid Shotblast Rubber Seals?

Shotblast rubber seals are products or components often produced in the form of cut or pressed gaskets, washers, strips, and extruded or moulded profiles and edge trims. Shotblast or Tan Para rubber seals can be used as gap fillers between uneven surfaces, as separators or barriers to prevent liquids, particles, or gases from escaping or penetrating the application, and in a number of vibration-dampening, sealing, and insulation applications. Solid shotblast rubber materials are produced from natural latex, creating a tan' coloured, soft rubber material - sometimes described as having a similar texture and appearance to the material used to manufacture elastic bands. This material has been formulated to have outstanding abrasion and tear resistance, making it a very robust and resilient material ideal for a range of sealing applications.

Why use Solid Shotblast Rubber Seals?

Solid shotblast rubber seals offer high tensile strength, excellent resistance to abrasion and tearing, and good resistance to weak chemicals, dilute acids, and alkalis. It is manufactured in a shore hardness of 45°, has a working temperature range of - 40°C to +85°C and is pre-manufactured in a wide range of standard thicknesses in roll form, from which most flat seals can be cut; however, spoke profiles will need to be made to order using moulding or extrusion methods.

Benefits of using Shotblast Rubber

- Can withstand harsh or abrasive media

- Working Temperature Range: -25°C to +70°C.

- Excellent abrasion resistance.

- Good strength and durability.

- High elasticity

- Excellent tear strength

Different Types of Shotblast Rubber Available

Black shotblast rubber - manufactured from a black abrasion-resistant grade natural rubber. This material, like the Tan variety, is highly durable, with excellent tear resistance and an operating temperature range of -40°C to +80°C, for use in the most demanding construction applications.

Advantages of Using Solid Shotblast Rubber Seals

Seals produced from solid Shotblast (Tan Para) rubber, or components cut from these rolls, offer many advantages to users. It is a strong, flexible, and highly abrasion-resistant natural rubber, even when used with harsh media, available in tan or black (tan being more readily available), with a hardness of around 45° to 50° shore, depending on the colour. Rolls of shotblast rubber are pre-manufactured in a range of thicknesses, allowing for quicker lead times for cut seals, as the splitting process used with sponge and foam conversion is eliminated. Shotblast rubber can also be moulded or extruded, meaning perfectly formed, identical seals can be produced in high or low quantities for use as shot-blast cabinet seals, wear or impact protection, tubes, pipes, chutes, scraper blades, etc.

Please contact us using the form below or by calling us on +44(0)1384 252555.