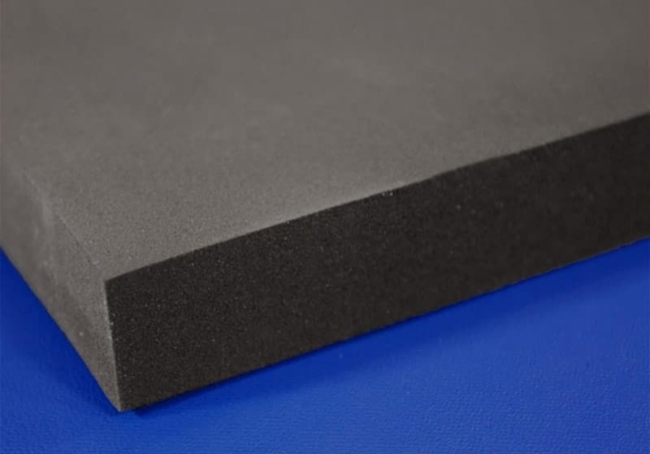

EPDM Foam Sheet

At Advanced Seals & Gaskets Ltd, we supply a wide range of EPDM medium density sponge sheets as part of our extensive catalogue of sheet materials. Our EPDM sponge sheets are converted from blocks using state-of-the-art splitting machines, allowing us to supply sheets starting from just 1mm thick in standard sizes of 2m x 1m, or cut down to bespoke dimensions and pads to suit specific applications.

Our on-site laminating service enables us to laminate layers of sponge for greater thicknesses and provide sheets coated with self-adhesives, foils, or laminated with other materials. EPDM sponge sheets are ideal for customers who need the flexibility to cut strips, gaskets, or pads on demand or cover larger surfaces with minimal joins.

What are EPDM Sponge Sheets?

EPDM stands for Ethylene Propylene Diene Monomer, a synthetic, closed-cell sponge material known for its strength and durability. The closed-cell structure makes EPDM ideal for internal and external sealing applications, as it provides effective air, gas, and water sealing even under minimal compression.

EPDM sponge is one of ASG’s core stock materials, available in blocks, sheets, and rolls, in thicknesses starting from 1mm, ensuring rapid despatch. Rolls provide customers with the flexibility to cut sheets as required, and sheets can be finished with foils, self-adhesives, or other materials depending on the application.

Product Enquiry

For information on EPDM Foam Sheet please complete the following quick enquiry or call us on +44(0)1384 252555.

The Benefits of EPDM Foam Sheet

- Colour: Black and white (medium density only)

- Density: 90 – 140kg/m³

- Flammability Tested: FMVSS 302

- Operating Temperature: -20°C to +85°C

- Thickness: 1mm – 50mm (without laminations)

- Environmental Resistances: Ozone, UV, weathering

- Chemical Resistances: Ketones, diluted acids, and alkalis

Full technical data is available upon request or downloadable via our online portal.

Why Use EPDM Foam Sheets?

EPDM sponge sheets are widely used to fill gaps and irregularities between surfaces, reduce noise, vibration, and shock, and seal against air, gas, dust, and liquids. They also cushion moving components, reducing friction and wear.

The closed-cell nitrogen-filled structure allows EPDM to maintain compression and recovery, creating a strong airtight and watertight seal. EPDM sheets are used across industries such as construction, automotive interiors, electronics, lighting, ventilation, glazing, and door seals.

The Benefits of Using EPDM Sponge Sheets

- Reduces noise, vibration, shock, and abrasion

- Flexible with excellent compression recovery

- Cost-effective and readily available

- Naturally compressible for airtight and watertight sealing

- Closed-cell structure prevents bacteria and mould growth

- Easy to convert into gaskets, pads, and strips

- Holds most adhesives well

The Advantages of Using EPDM Sponge Sheets

EPDM sponge is a strong, synthetic, closed-cell material, ideal for internal and external sealing applications. It has a long lifespan, is free from dust and fibres, and can be manufactured in various sizes and thicknesses. Laminations with foils or self-adhesives can be applied to one or both faces, and thicker sheets can be laminated together or combined with other materials for specialized applications.

EPDM sheets are air and watertight, age-resistant, UV-stable, and operate across a wide temperature range of -20°C to +85°C. They also have excellent electrical insulation properties, resistance to ketones, diluted acids, alkalis, ozone, UV, and weathering, and meet FMVSS 302 and UL94 HBF flammability standards.

Grades of EPDM Sponge Sheets Available

ASG stocks a range of EPDM sponge grades and densities to suit different applications:

- High Temperature EPDM Foam: Closed-cell, flexible at low temperatures, with a temperature range of -50°C to +128°C. Excellent mechanical, thermal, and insulation properties, suitable for HVAC, refrigeration, pipelines, automotive, white goods, and construction.

- Semi-Open Cell EPDM: Combines the flexibility of open-cell with the sealing capabilities of closed-cell once compressed. Allows air, dust, and moisture ingress until compressed, after which it behaves as closed-cell.

- Firm Grade EPDM Foam: High resilience, increased tear strength, suitable for automotive, marine, defence, white goods, and construction applications.

Please contact us using the form below or by calling us on +44(0)1384 252555.