nylon plastic strips

nylon plastic strips

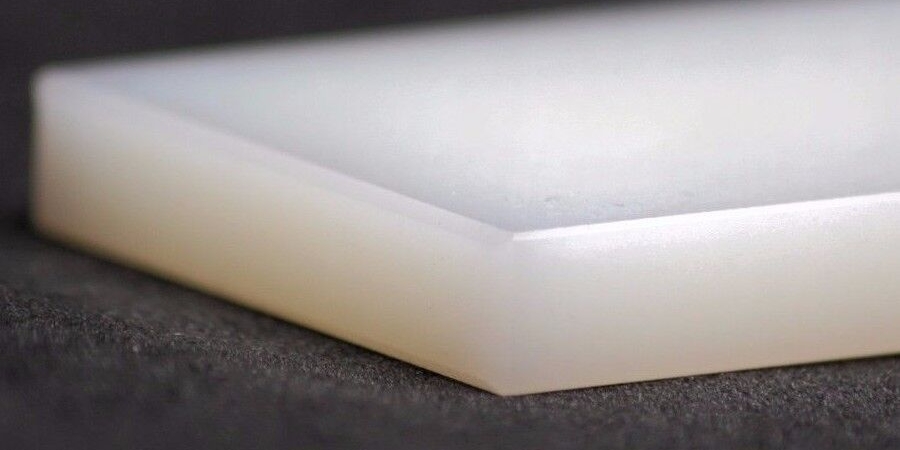

Plastics strips make up a small selection of products manufactured and supplied by Advanced Seals & Gaskets Ltd, which are available in many grades, colours, thicknesses and finishes, with one type being Nylon Plastic.

Nylon plastic strips are amongst the most popular plastic used within the engineering sector as it is available in a number of standard sheet sizes from 250mm x 250mm up to 2000mm x 1220, in thicknesses from 1mm to 100mm thick which can be used to cut down into strips.

As Nylon plastic can be manufactured by either casting or extruding, strips can also be made available in almost any bespoke length and thickness. Using our customers drawings, samples or dimensions, one of our many on-site saws, presses or CNC machines, we are able to convert Nylon plastic strips from sheets of material supplied with the option of a plain or self-adhesive backed finish.

Characteristics of Nylon Plastic

- Colours: black/natural as standard

- Texture: smooth or various textured options can be cast or extruded

- Thicknesses: 1mm - 100mm

Grades of ABS available:

- Flame retardant options; our fire retardant products have a UL94-V0 fire grade rating

- Metal Detectable - for food/pharmaceutical applications

Temperature Range:

- Melt Temperature 250-290 (℃)

- Mould Temperature 50-90(℃)

- Chemical Resistances: Good resistance to wear, impact, shock, chemicals

Full technical data can be supplied upon request,

or downloaded from our online portal.

What are Nylon Plastic Strips?

Nylon plastics can be manufactured in a range of grades, making them one of the most flexible and widely used polymers within the engineering and electrical manufacturing industries. Nylon plastics are often cut into a range of strips as they are lightweight and as with most plastics, a preferred alternative to metal due to their durability and resistance to weathering and corrosion. Nylon plastic strips are often purchased for use in a similar way to a gasket, whereby they are used to create a seal between surfaces, fill irregularities or act as insulation such as electrical barriers.

Why use Nylon Plastic Strips?

Plastics are so popular as each type is manufactured using different compounds in order to produce a product with specific properties. Nylon plastic strips are preferred for a number of reasons, they offer high tensile strength, stiffness and good mechanical properties.

Nylon plastic strips provide moderate resistance to chemicals, are electrically insulating and perform well when exposed to heat for prolonged periods, the high melting temperature makes it a great substitute for metals in many high-temperature environments.

Nylon plastic strips are relatively easy to machine using the right tools and can therefore be used in the production of anti-vibration blocks or electrical insulation barrier strips, as well as many times of seals and fittings. As Nylon plastic offers outstanding bearing and wear properties, components can often be found used as an alternative to metal fixtures and fittings which are resistant to corrosion, reduce the need for additional lubrication and will reduce the wear on moving parts.

Other Types of Plastic Available

Advanced Seals & Gaskets work with a multitude of material manufacturers and suppliers, giving our customers more choice of plastic sheeting - our most popular materials being:

- PTFE

- PVC

- Polycarbonate

- Polypropylene

- HIPS (High Impact Polystyrene)

- ABS

- Polyester

- Acetal

- Acrylic

- Nylatron

Benefits of Using Nylon Plastic

- Available in a choice of grades including extruded metal detectable (primarily used in food and pharmaceutical processing operations) and flame retardant

- high chemical resistance

- high operating temperature

- good electrical insulating

- Good machinability

- Strong

- Excellent bearing and wear properties

Advantages of Using Nylon Plastic Strips

Plastics are used within a number of industries, with Nylon being one of the most utilised plastics due to its extreme high-temperature resistance and strength. Strips made from Nylon plastic are often used to replace metal bearings, jigs and fixtures as they will not corrode through weathering, water or chemical exposures.

Nylon plastic parts made from general purpose grade are often utilised for mechanical construction and maintenance due to its optimal combination of mechanical strength, stiffness, toughness, mechanical damping properties and wear resistance together with a good electrical insulating ability and a good chemical resistance.

Using Nylon plastic strips can reduce the need for additional lubrication when used between moving parts, reduce the weight of a product by replacing metal parts and fixtures with plastic ones, reduce noise and wear caused by abrasion or impact. Nylon plastic strips are very strong, offering some flex and recovery, making them more resistant to impact in comparison to metal alternatives, absorbing shock, noise and vibration. Some popular industries utilising Nylon plastic strips include machinery parts in engineering, aircraft, automotive and electronics industries.

Please contact us using the form below or by calling us on +44(0)1384 252555.