Polypropylene Strip

Polypropylene Strip

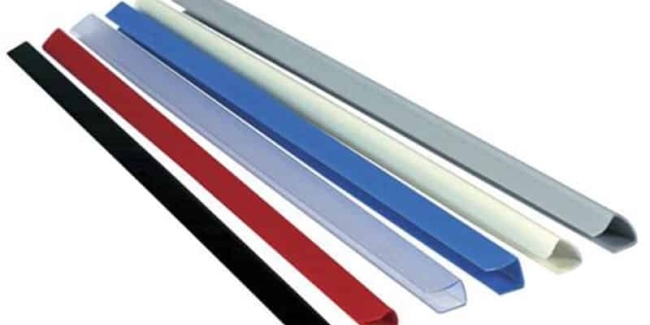

Alongside the multitude of sponge, foam and rubber components converted by Advanced Seals & Gaskets Ltd, a range of cut plastic strips are also available, including our Polypropylene Strip.

Our plastic strips can be cut using one of many various grades and colours with one type being Polypropylene Plastic (PP). Polypropylene (PP) is one of the most commonly used thermoplastics in the world.

Polypropylene uses range from plastic packaging, plastic parts for machinery and equipment and medical supplies to name a few. Polypropylene sheet is available in two versatile grades, PPH (Homopolymer) and PPC (Copolymer), and depending on the grade available in a choice of colours including Natural, Black, White, Beige, and sheets sizes up to 4 metres x 2 metres in size and 200mm in thickness from which strips can be cut.

Other non-standard strip sizes with different textures and profiles can also be supplied to order as Polypropylene plastic can also be moulded into bespoke finishes for use across several industry sectors. Using customers' drawings or dimensions, one of our many on-site saws, presses or CNC machines, we are able to convert and supply Polypropylene cut strips in a plain or self adhesive finish.

Product Enquiry

For information on Polypropylene Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Polypropylene Plastic:

- Colour: Anthracite

- Density: <90KG/M³

- Fire Propagation Index: <12

- Operating Temperature: -30°C to 100ºC

- Thickness: 1mm – 100mm (can be laminated for greater thickness)

Full technical data can be supplied upon request, or downloaded from our online portal.

What are Polypropylene Strip?

these Polypropylene plastic strips are often purchased for use in the same way as a gasket, whereby they are used to create a seal between uneven surfaces and fill irregularities or to act as insulation such as electrical barriers.

the Stripes is a rigid, semi-crystalline thermoplastic meaning it can be melted and re-formed repeatedly, therefore moulded into perfectly formed strips with bespoke finishes.

Polypropylene plastic strips are used in a range of domestic and industrial applications and are popular due to its highly flexible properties, lighter density and ability to withstand conversion using a range of fabrication techniques, its is also known as the ‘steel’ of the plastic industry, because of its strength and as it can be used and manipulated and utilised in so many different ways.

Why use Polypropylene Strip?

The Polypropylene Plastic strips are a tough, flexible and durable material offering excellent fatigue resistance and elasticity. These strips have a high insulation properties making it safe to use to manufacture plastic casing in electrical goods, within electrical appliances and even within marine, automotive and medical industries.

aswell as Polypropylene plastics and components cut from such as strips have a number of other excellent characteristics including chemical resistance, fatigue resistance and transmissibility where the transfer of light or visibility are important.

Polypropylene plastic strips are resilient to general wear and tear and ideal for items that must undergo higher levels of physical stress, they are also resilient against mildew, mould, rot and bacteria, usually FDA approved offering a working temperature range of -20°C up to +80°C.

Other types of plastic strips available

Advanced Seals & Gaskets work with a multitude of material manufacturers and suppliers, giving our customers more choice of plastic sheeting - our most popular materials being:

- PTFE

- PVC

- Nylon

- Polycarbonate

- HIPS (High Impact Polystyrene)

- ABS

- Polyester

- Acetal

- Acrylic

- Nylatron

Benefits of using Polypropylene Strip

- Can be manufactured in a range of transparent colours

- Resistant to chemicals including Diluted bases and acids

- Flame retardant

- Strong, Durable and Impact resistant

- Weather resistant

- Good machinability and can be moulded

- FDA approved

Advantages of using Polypropylene Strip

Strips cut using Polypropylene provide a number of excellent properties and bring many advantages to using them. Polypropylene strips offer excellent fatigue resistance, elasticity, strength and durability making it perfect for use in a wide range of industries and applications - even those within demanding environments.

Also Polypropylene Plastic strips have high insulation properties making them safe for use within machinery, electrical appliances and electrical equipment.

These Polypropylene strips are so strong they can be twisted 360 degrees without snapping therefore perfect for in applications where they will be exposed to repetitive stress, movement and manipulation.

The Polypropylene strips are waterproof and extremely resistant to moisture absorption, which is why it can often be found used in aquatic and marine applications. To manufacture parts for packaging. High resistance to chemical corrosion makes PP strips a popular choice for packaging and within machinery used in the production of cleaning products, bleaches, first-aid products and medicines.

Polypropylene can also be manufactured in a broad spectrum of colours in a transparent or opaque finish. it’is a relatively cheap material to manufacture therefore great for the production of mass produced or products or those which need replacing regularly.

Please contact us using the form below or by calling us on +44(0)1384 252555.