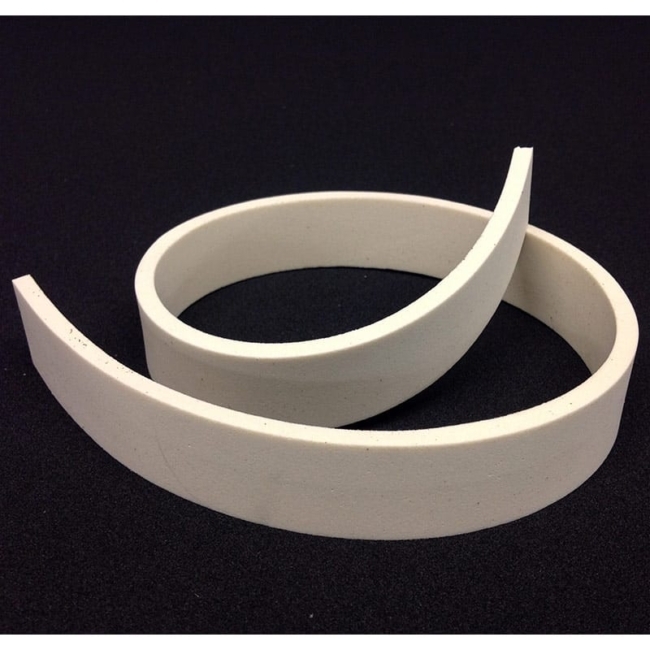

Food Quality Natural Rubber Strip

Food Quality Natural Rubber Strip

Here at Advanced Seals & Gaskets Ltd, we manufacture 1000’s high-quality food quality solid natural rubber strips, sometimes referred to as gasket strip, sealing strip or isolation strip. Food quality solid natural rubber strips are all manufactured by our highly skilled workforce using state of the art machinery, following our customer samples of drawings.

We can produce bespoke food quality solid natural rubber strips using our bandsaws, strippers, log cutters and even presses depending upon the size and quantity required. In-house production allows us to closely oversee the whole production process to ensure that we consistently produce high quality, competitively priced solid natural rubber strips.

Our food quality natural rubber strips are cut from rolls, which are manufactured in a range of standard thicknesses starting at just 1mm, these can be supplied coated with self-adhesive backing or laminated to other materials, which can then be cut into strips in widths starting at 4mm wide and in a choice of 10 meter long continuous coils or pre-cut shorter lengths.

What are Food Quality Solid Natural Rubber Strips?

Solid natural rubber is produced using latex secretions from certain types of plants which are ground together with compounding ingredients before the rubber is shaped and cured.

Food quality natural rubber is manufactured in roll form from which products such as strips can be cut using a selection of in-house machinery.

Food quality solid natural rubber strips are cut from sheets or rolls to order, meaning we can supply them to meet your exact specifications in terms of lead time, size and finish.

Food quality solid natural rubber strips can be used for noise or vibration control applications or as gaskets, placed between two surfaces to create a low-pressure seal preventing the leakage of dust, liquids or gas.

Product Enquiry

For information on Food Quality Natural Rubber Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: White

- Standards: EU1935:2004 20/23/26 & FDA CFR 177 Sub Part C 177.260

- Properties: Good mechanical strength, abrasion resistance, tear resistance, high tensile strength, good resistance to alcohols, ketones and organic acids

- Shore Hardness: 60° shore

- Working Temperature range: -25°C to +80°C

Full technical data can be supplied upon request,

or downloaded from our online portal.

Why use Food Quality Solid Natural Rubber Strips?

Customers will often request their strips are manufactured using Food quality solid natural rubber as it is a high quality, white material which meets EU1935:2004 20/20/26 and FDA CFR 177 Sub Part C 177 standards ensuring the material is safe for use in food and pharmaceutical applications, where it’s colour helps with the detection of dirt and foreign bodies whilst protecting the ingredients from taste and odour contamination.

Food quality solid natural rubber strips offer excellent tear and abrasion resistance, tensile strength, with good resistance against moderate chemicals, wet & dry organic acids, alcohol and ketones.

This material can withstand moderate heat applications, but is not recommended for you with stronger acids, oils, grease, ozone exposure of hydrocarbons.

Benefits of using Food Quality Solid Natural Rubber

- Solid natural rubber strips are suitable for food and pharmaceutical applications

- Durable moderate temperatures

- Solid natural rubber strips are abrasion & tear resistant

- High tensile strength

- Good resistance to alcohols, ketones & organic acids

- Solid natural rubber strips are available in a range of thicknesses

Advantages of using Food Quality Solid Natural Rubber strips

Food quality natural rubber strips (NR) are FDA approved, white in colour allowing for dirt or foreign object detection, it is both tasteless and odourless therefore protecting products from contamination.

Food quality natural rubber strips offer excellent tear and abrasion resistance, tensile strength, good resistance against moderate chemicals, wet & dry organic acids, alcohol and ketones, and an operating temperature range of -25°C to +80°C.

This material can withstand moderate heat applications, but is not recommended for you with stronger acids, oils, grease, ozone exposure of hydrocarbons - where particularly oily or greasy ingredients are involved, a food-grade nitrile rubber may be more suitable.

The material is manufactured in a range of thicknesses which can be converted into parts such as solid natural rubber strips for use with sealing or within machinery to help reduce abrasion, movement and vibration between moving parts.

Different grades of Food Quality Solid Rubber

As ASG works with a network of material manufacturers and suppliers, we are able to offer customers a choice of neoprene rubber types to choose from, some of the most popular include:

Neoprene (CR) is white in colour, and conforms to EC and FDA regulations for use within the food processing and pharmaceutical industries. Properties including resistance to fats, greases and vegetable oils, combined with higher tensile strength and wider working temperature range of -30°C up to +130°C make it a popular material to use

Nitrile Food quality nitrile rubber offers excellent resistance to animal fats, vegetable/fish oils and greases, as well as higher tensile strength and resistance to high temperatures

EPDM - Food quality EPDM is available in blue and white options. This synthetic material is suitable for use in food and pharmaceutical processing applications. Food quality EPDM offers good resistance to animal and vegetable oils, iis non-toxic and has a working temperature of -25°C up to +140°C.

Silicone - Most silicone rubber can be used for consumable handling, processing and packaging applications and meet FDA standard 177.2600 and EC 1935/2004. The material performs well and remains flexible at extreme temperatures, has good chemical resistance ( including ammonia gas, sodium sulfate, and vinegar), its smooth non-porous surface offers a natural resistance to bacteria build-up and is odourless and tasteless.

Please contact us using the form below or by calling us on +44(0)1384 252555.