High Load-Bearing Foam Washers

Advanced Seals & Gaskets Ltd manufactures and supplies high-quality High Load Bearing (HLB) foam washers using polyurethane (PU) materials, which are among the most widely used foams in applications such as furniture, automotive interiors, and industrial cushioning.

HLB PU foam is manufactured in large blocks (2.3m x 2m or 2.3m x 1m), which can be split into sheets up to 100mm thick or laminated for greater thicknesses. These sheets can also be joined to form rolls, from which washers are cut precisely to customer specifications.

Our in-house production facilities allow washers to be made from drawings, samples, or measurements, ensuring each product meets the required size, thickness, and functionality. Depending on the quantity, washers can be produced using presses, bandsaws, or CNC machines, and supplied as loose cut parts or kiss-cut on rolls for high-volume or assembly line applications.

HLB PU foam washers can be finished as plain, laminated to increase thickness, combined with other materials, or coated with self-adhesives or foils before cutting.

Product Enquiry

For information on High Load-Bearing Foam Washers please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of High-Load-Bearing PU

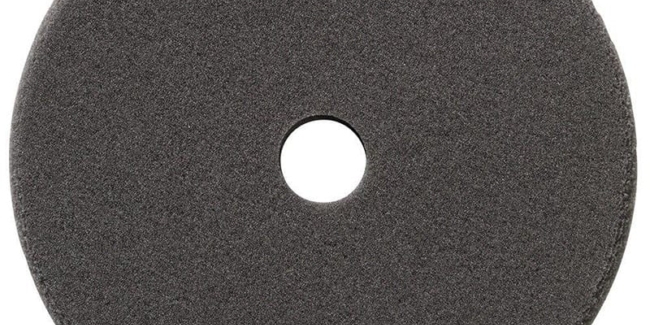

- Standard Colour: Dark Grey

- Density: 20–24 kg/m³

- Nominal Hardness: 215–290 Newtons (BS EN ISO 2439:2008 Method B)

- Tensile Strength: ≥110 KPa

- Elongation at Break: ≥100%

- Force @ 25% Compression: 45–60 lb (D3574-81 Test B1)

Complete technical data available on request or via our online portal.

What What are High Load Bearing Foam Washers?

High Load Bearing foam washers are flat rings with an Outer Diameter (OD), an Inner Diameter (ID), and a thickness, designed to be placed between surfaces for cushioning, load distribution, and sealing.

HLB PU washers can be produced from as thin as 2mm, with options for plain or self-adhesive finishes. Multiple layers of material can also be laminated to create bespoke washers with varying firmness.

Polyurethane foam is made from polyol and diisocyanate, forming a durable, high-density foam that provides shock absorption, resilience, and mechanical support across a wide range of industries.

Why Use High-Load Bearing Foam Washers?

HLB foam washers are preferred due to their load-bearing capacity and impact resistance. The viscoelastic properties of high-density PU foam allow it to absorb force and recover its shape, making it ideal for:

- Automotive interiors and seating

- Industrial buffer or impact pads

- Seals, gaskets, and vibration-damping

- Packaging and protection for delicate electronics

HLB foam can also be laminated with lower-density foams to provide custom levels of firmness, creating bespoke washers suited to specific applications.

Alternative PU & Packaging Foams

- Acoustic Foam

- Egg Box Foam

- Pick & Pluck Foam

- Basotech Foam

- Polyester Foam

- Polyether Foam

- Recon Foam

- Reticulated (Retic) Foam

Benefits of Using High-Load-Bearing Polyurethane Foam

- Durable and sturdy

- Excellent viscoelasticity and recovery

- Available in multiple sheet sizes

- Can be laminated to other materials

- FR and Anti-Static grades available

- Easy to cut and process

Advantages of Using High-Load-Bearing Polyurethane Foam Washers

High-load-bearing foam washers are used not only as mechanical or engineering components but also in commercial and residential seating applications. Their viscoelastic properties make them suitable for:

- Automotive applications (interior cushioning, vibration absorption)

- Industrial impact pads, seals, and gaskets

- Protective packaging for fragile electronics

- Sound and vibration dampening

- Cushioning and sealing in aerospace, machinery, and appliances

Available in custom densities and thicknesses, HLB PU washers can also be laminated for bespoke firmness levels, ensuring optimal performance in critical applications.

Please contact us using the form below or by calling us on +44(0)1384 252555.