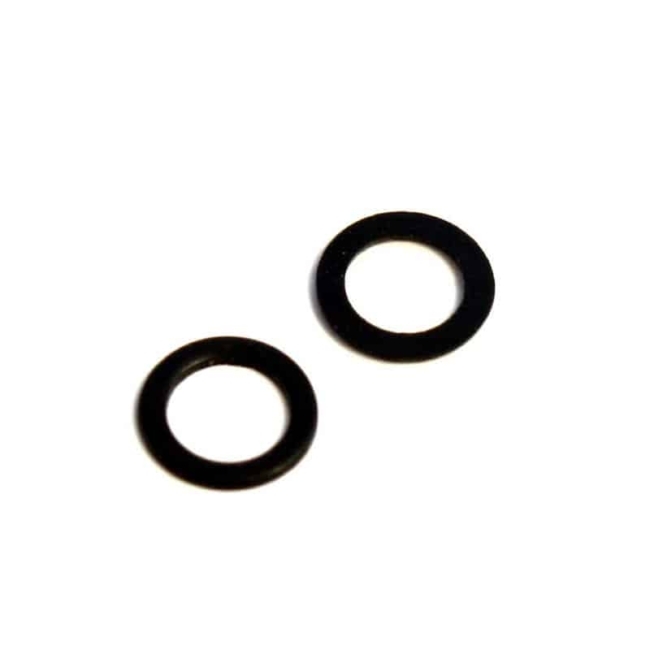

Hypalon Washers

High-Quality Hypalon Rubber Washers from Advanced Seals & Gaskets

At Advanced Seals & Gaskets Ltd, we manufacture and supply Hypalon washers for a wide range of industrial applications. Our washers are produced in-house, allowing us to create custom washers to meet exact specifications based on customer drawings, samples, or measurements.

We use a variety of presses, CNC machines, and kiss-cut machinery to manufacture washers, from one-off samples to large batch runs. Hypalon rubber washers are widely used across industries for sealing against dust, air, and moisture, gap-filling between uneven surfaces, and reducing noise and vibration.

Washers can be supplied plain, or with foils, self-adhesives, or laminated to other materials, depending on the requirements. They can also be delivered as loosely packed parts or kiss-cut on rolls for ease of use.

What Are Hypalon Rubber Washers?

Hypalon rubber washers are flat, circular rings with a central hole, designed to be placed between two surfaces. These washers:

- Create a level surface for nuts, bolts, and other fasteners

- Act as spacers, allowing for the proper fit of fasteners

- Provide air-tight and liquid-tight seals in pipework and other applications.

- Reduce stress and potential damage to fastened materials.

- Absorb vibration, particularly where hard surfaces move against each other.

Hypalon rubber, also known as chlorosulfonated polyethylene (CSPE), is a high-quality synthetic elastomer produced by reacting polyethylene with chlorine and sulfur dioxide. This process gives Hypalon its chemical inertness, fire resistance, and durability.

Product Enquiry

For information on Hypalon Washers please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Black

- Shore Hardness: 65°

- Working Temperature Range: -30°C to +140°C

- Resistances: UV, weathering, extreme temperatures, chemicals, oils

- Tensile Strength: High

- Flammability: Self-extinguishing

- Thickness: From 1mm

- Complete technical data available upon request or via our online portal.

Why Use Hypalon Rubber Washers?

Hypalon washers are highly valued for their exceptional resistance to harsh environments, including:

- Ozone and UV exposure

- Weathering and temperature extremes (-30°C to +140°C)

- Chemical and oil exposure

The material combines the moisture resistance and dielectric strength of polyethylene with the oil resistance and low flammability properties provided by chlorine, making Hypalon washers suitable for industrial, automotive, and electrical applications.

Advantages of Using Hypalon Washers

Using Hypalon rubber for washers offers several advantages:

- Chemical inertness – resists acids, alkalis, and solvents

- Excellent weather and ozone resistance – suitable for outdoor and harsh environments

- Wide operating temperature range – performs reliably under high and low temperatures.

- High tensile strength – durable and long-lasting

- Electrical insulation properties – safe for specific electrical applications

- Low flammability – self-extinguishing for enhanced safety

Benefits of Hypalon Washers

- Excellent resistance to ozone, weathering, and UV exposure

- Strong and durable for long-term use

- Resistant to aggressive chemicals, oils, and solvents

- Wide temperature range for industrial applications

- Can absorb vibration and impact

- Provides reliable electrical insulation in specific applications

At Advanced Seals & Gaskets Ltd, our Hypalon washers are manufactured to meet precise customer requirements, offering a combination of durability, chemical resistance, and excellent sealing properties. These washers are perfect for applications where high performance under extreme conditions is essential.

Please contact us using the form below or by calling us on +44(0)1384 252555.