Plastazote (LD60) Polyethylene Foam

Advanced Seals & Gaskets Ltd work with a multitude of reputable material manufacturers and suppliers, enabling us to offer a range of materials in many grades, densities and colours. One of the more popular materials includes various types of Polyethylene (PE) foam, one of which includes Plastazote foam in a 60kg density or LD60 (plastazote LD60 polyethylene foam) as it is more commonly referred to.

This material is a closed-cell, cross-linked polyethylene foam which is incredibly lightweight, and free from chemical agents which enable customers to use this material in highly sensitive environments. Plastazote LD60 polyethylene foam is manufactured and stocked in block form from which we can convert sheets and rolls of various thicknesses. As we offer in-house conversion and lamination services, we can not only split materials down, we can also laminate layers together and apply self-adhesives or foil facings.

Our onsite facilities consist of a number of presses, log cutters, strippers, bandsaws and CNC machines from which we can produce a number of plastazote LD60 polyethylene foam products including gaskets, washers, strips, pads and fabrications.

What is Plastazote (LD60) Polyethylene Foam?

Plastazote LD60 foam is a type of cross-linked, closed-cell polyethylene foam, man-made using crude oil into which nitrogen is blown and the foam is expanded.

This manufacturing process produces a tough and flexible material. When the plastazote LD60 polyethylene foam has compressed each nitrogen-filled cell acts like a balloon, causing the foam to bounce back to its original shape.

Being a closed-cell structure of plastazote means it is impenetrable to air and moisture and will not allow liquids to pass through or be absorbed. Plastazote LD60 polyethylene foam like other polyethylene foams are manufactured in a range of densities for use in different applications.

The density of the foam is measured as the weight or mass of the foam across its entire volume or within a cubic meter (m3). The denser the foam, the heavier and more compact the material is, this can have an effect on some of the properties of the material and how it performs.

Material Enquiry

For information on Plastazote (LD60) Polyethylene Foam please complete the following quick enquiry or call us on +44(0)1384 252555.

Specification & Key Characteristics

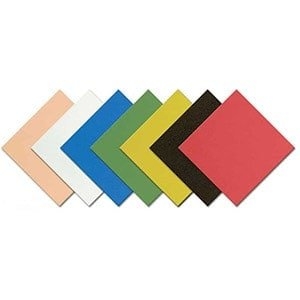

- Colours: Black and white as standard (red, blue, yellow and green, pink, etc) can be supplied upon request

- Density: 60g

- Cell Structure: closed-cell

- Tensile Strength: 650 kPa

- Tensile Elongation: 165 %

- Tear Strength: 1720 N/m

- Temperature Range: -70℃ - +105℃

- Flammability: FMVSS302 (4mm)

Full technical data can be supplied upon request,

or downloaded from our online portal.

Help and guidance

If you would like to speak to a representative to discuss your specific application or requirements please call our sales office direct on 01384 469100, alternatively you can send an E-mail. Simply click on the link and forward us your details along with your question and we will contact you immediately.

Samples - Technical Plastazote (LD60) Polyethylene Foam

Samples can be submitted for testing upon request.

Call now for sample requests or further help.

Why use Plastazote (LD60) Polyethylene Foam?

LD60 Plastazote foam offers all of the features of LD45, but possesses higher density and is commonly used for heavy-duty packaging inserts such as for toolbox liners or handling military items such as explosives.

Plastazote LD60 polyethylene foam is a low-density foam that can be easily split, cut and shaped. It offers excellent recovery following compression and impact and good resistance to a range of chemicals, solvents, acids, alkalies and some oils, meaning it can be utilised in many applications.

All Plastazote materials, including plastazote LD60 polyethylene foam, are lightweight and free from chemical agents, therefore used in many ‘clean’ applications such as food, pharmaceutical and science. Plastazote LD60 polyethylene foam offers great thermal properties and offers high levels of vibration and shock absorption for use as protective packaging or for cutting into gaskets and other seals.

Advantages of using Plastazote (LD60) Polyethylene Foam

Using plastazote LD60 foam offers countless advantages and is highly utilised in numerous industries and applications, Plastazote foam is a man-made material, designed to suit a range of requirements and is available in a choice of grades, densities and colours to suit. Plastazote LD60 polyethylene foam is odourless, lightweight, buoyant, non-toxic and offers resistance to many oils, solvents, acids and alkalis.

Its closed-cell surface does not allow the absorption of liquids and is easy to keep clean, as well as being weatherproof and UV stable. Plastazote LD60 polyethylene foam is usually preferred for heavy-duty protective packaging such as case inserts for holding tools, the material has excellent recovery from repetitive impact, resistance to abrasion and is highly energy absorbent, which also gives it good thermal insulation properties.

Using these materials for packaging and transporting goods offers customers cost-saving benefits as there is a reduction in damage to products whilst in transit or storage.

Typical Applications for Plastazote Polyethylene foam:

LD60 Plastazote polyethylene foam is most commonly found used in packaging applications, being low-density plastazote LD60 polyethylene foam can be easily cut and manipulated to fit around delicate or fragile products. Other applications can include:

- Making costumes or props

- Displays

- Used in the manufacture of sports equipment

- Water repellent and buoyant for use as floatation or buoyancy aids

- Used for surface protection and components for medical and healthcare applications

- Footwear lining

- Electronics packaging

Benefits of using Plastazote (LD60) Polyethylene Foam?

- Lightweight & durable

- Good impact and shock absorbing properties

- Water repellent and buoyant

- Excellent chemical, oils, acids, alkalis and solvent resistance

- Good thermal insulation

- Non-toxic, low odour and low dust shedding

- Easy to cut, convert & shape

Different Grades of Polyethylene Available

Having a network of manufacturers and suppliers, allows ASG to offer a full range of polyethylene materials, many of which are readily available from stock for a quick turnaround. Below is just a selection of some of our popular polyethylene material types we can offer:

- Polyethylene (Block foam)

- Anti-static

- Ethafoam

- Eva foam

- Flame retardant

- Chemically cross-linked

- Plastazote (densities from 15kg to 70kg)

- Stratocell

Please contact us using the form below or by calling us on +44(0)1384 252555.