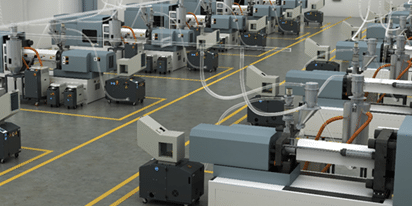

Automatic Presses

At Advanced Seals & Gaskets Ltd, we are proud to offer advanced manufacturing capabilities, highlighted by our impressive fleet of Automatic Presses. These cutting-edge machines are designed for optimal efficiency, high precision, and exceptional output quality across a wide range of applications.

Our Automatic Presses are incredibly versatile, allowing us to manufacture an extensive variety of components, including kiss-cut parts, crush-cut items, gaskets, strips, washers, plain shapes, and components with self-adhesive backing. Whether you require finger lift tabs or pre-picked or unpicked products, these presses deliver consistent, high-specification results through continuous, rapid production.

What are Automatic Presses?

Automatic presses are highly efficient machines designed to perform repetitive production tasks with remarkable accuracy and speed. Featuring built-in automation, they streamline manufacturing processes by minimising human error and ensuring a consistent standard of quality. Their ability to manage a wide range of materials and tasks makes them vital in foam and rubber processing environments.

Benefits of Automatic Presses

- Efficiency: Speeds up production lines by automating repeat processes, reducing cycle times and enhancing productivity.

- Consistency: Ensures uniformity across all produced parts by maintaining tight control over cutting and forming operations.

- Precision: Achieves extremely accurate cuts and shapes, ideal for applications with strict tolerances and complex specifications.

- Cost-Effectiveness: Reduces reliance on manual labour and optimises material use, minimising waste and lowering production costs.

- High Volume Output: Designed to handle large-scale production runs with ease, keeping pace with customer demand.

- Versatility: Easily adaptable to different tasks and custom component configurations.

- Quality Control: Integrated monitoring ensures all products meet the required quality and dimensional standards.

- Flexibility: Quick to reconfigure between jobs, allowing manufacturers to shift production without extended downtime.

- Continuous Production: Supports 24/7 operation with minimal interruptions, maximising operational output.

- Software Integration: Can be connected to digital systems for real-time tracking, data analysis, and inventory control.

- ISO Standards: Complies with ISO specifications to maintain top-level quality and operational excellence.

Advantages of Automatic Presses

Automatic presses enhance manufacturing through their adaptability, precision, and reliability. Their automated nature allows for faster turnaround times, consistent product quality, and the ability to tackle complex projects with minimal human intervention. These qualities make automatic presses indispensable for modern manufacturing needs—particularly within the foam and rubber industries.

Capabilities of Automatic Presses

- Kiss Cutting: Allows partial cuts through the material without slicing through the backing—ideal for peel-and-stick products.

- Crush Cutting: Enables shaping of materials without a dedicated die, making it a fast and economical option for many applications.

- Gasket Production: Produces precise, uniform gaskets that meet rigorous industrial specifications.

- Strips and Washers: Fabricates various sizes of strips and washers quickly and consistently.

- Plain & Self-Adhesive Products: Creates both non-adhesive parts and those with self-adhesive backing for easy application.

- Finger Lift Tabs: Cuts products designed with tabs that make peeling back adhesive liners easy and efficient.

- Continuous & Rapid Output: Perfect for handling ongoing production runs with high-volume requirements.

- Quality Assurance: PrConducts line checks to ensure all items meet defined standards before completion.

- Customisation: Easily reprogrammed for custom shapes, allowing bespoke solutions to be manufactured efficiently.

- Increased Competitiveness: Speeds up production, lowers costs, and enhances customer satisfaction by delivering precise and timely products.

- ISO 9001 Compliance: Meets the rigorous standards of the ISO 9001 Quality Management System, reinforcing our commitment to consistent quality and process control.

Please contact us using the form below or by calling us on +44(0)1384 252555.