Polyethylene Foam Pads – Cushioning & Sealing Components

Alveo Foam Pads

Anti-Static Foam Pads

Conductive Foam Pads

Ethafoam Pads

EVA Polyethylene Foam Pads

Evazote Foam Pads

Flame Retardent Plastazote Foam Pads

Flame Retardant Polyethylene Foam Pads

GA25 Polyethylene Foam Pads

Plastazote Foam Pads

Polyethylene Foam Pads – Industrial Cushioning & Sealing

Static Dissipative Foam Pads

Stratocell Foam Pads

Foam Pad Manufacturers

Advanced Seals & Gaskets Ltd are proud to be one of the UK’s leading manufacturers of polyethene foam products, one of which includes polyethene foam pads. Our pads are produced on-site using drawings, samples or dimensions supplied by our customers ensuring the final product is to their exact specification. Depending upon the size and quantity of pads required, one of our many presses, bandsaws or CNC machines can be used to manufacture the final product to the highest quality of finish, from one-off samples to multiple batches runs, which can be supplied as loosely cut parts, or kiss-cut on rolls where a high quantity is required or for use on fast-paced assembly lines.

What are Polyethylene Foam Pads?

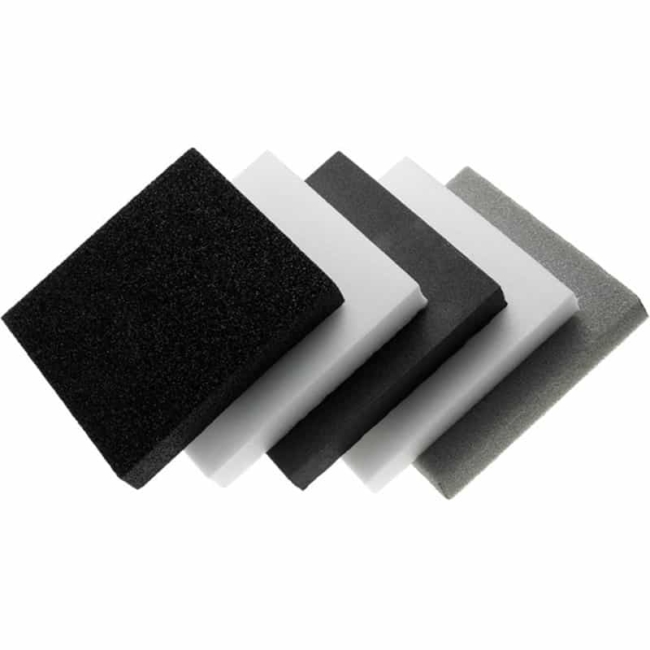

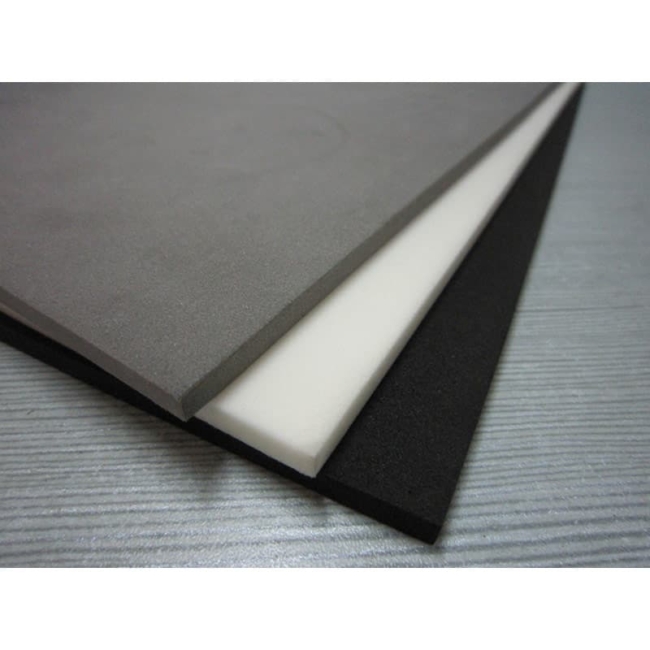

Polyethylene foam pads are manufactured from high quality, lightweight closed-cell material, which is flexible, has a number of resistances and insulation properties as well as being available in a variety of grades, densities, colours. Our polyethylene foam pads can be produced as squares or rectangles with the option of radius corners, and also as circular or oval-shaped pads or ‘discs’, in a range of thicknesses. Manufacturing pads in-house even means we can supply them in a plain or self-adhesive backed finish and even laminate multiple types of material together to create bespoke and unique versions of composite pads.

Why use Polyethylene Foam Pads

Polyethylene foam pads come in a range of grades and densities offering a range of properties for different applications. Polyethylene foam pads have a low compression set, resistance to water, some oils, chemicals and weather as well as being an excellent thermal insulation material. As polyethylene is a closed-cell material, it has good tear resistance and doesn’t support mold or fungus growth. Different variants of polyethylene include FDA grades for use with food, beverage and pharmaceutical applications, Flame Retardant and anti-static.

Grades

Having a network of manufacturers and suppliers, allows ASG to offer a full range of polyethylene pads. A selection of some of our popular polyethylene materials used for pad production include:

Alveo

Anti-static

Ethafoam

Eva foam

Flame retardant

Chemically cross-linked

Plastazote

Stratocell

Benefits of Polyethyelene Foam Pads

Polyethylene foam pads are often utilised in the same way as a gasket whereby it provides water, air and dust-tight seal, fills gaps and offers to cushion between surfaces and fittings. Polyethylene foam pads offer end users a huge number of benefits, it’s a non-toxic, high quality, lightweight material, which has good water, ozone, UV, weathering, grease and chemical resistance. Polyethylene has a wide operating temperature range, with higher temperature and flame retardant variants also available. Due to the number of grades on offer, polyethylene foam pads can be found in most applications where weather-resistant, acoustic and thermal insulation and tight sealing is required.