Adhesive Tapes

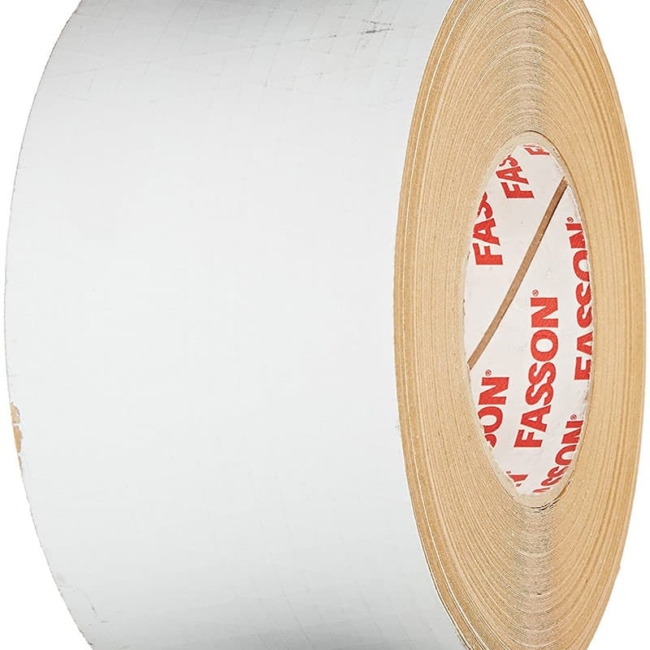

Fasson Adhesive

3M Adhesive Tape – Reliable and Versatile Bonding Solutions

Polypropylene Adhesive Tape – Reliable, Durable & Versatile

Scrim Adhesive

Transfer Adhesive – Precision, Strength & Versatility

Aluminium Foil Tape – Heat-Resistant & Durable Foil Adhesive Tape

Double-Sided Foam Tape – Strong, Versatile & Durable Adhesive

FT349 High Tack Adhesive Rolls

High Tack & Low Tack Adhesive Solutions – Hick Track Adhesive

Hot Melt Scrim Adhesive

Hot Melt Adhesive Tape

Hot Melt Transfer Adhesive

Acrylic Adhesive Tape

Perm Peel Tape

Protection Film Tape

Solvent Acrylic Adhesive Tape

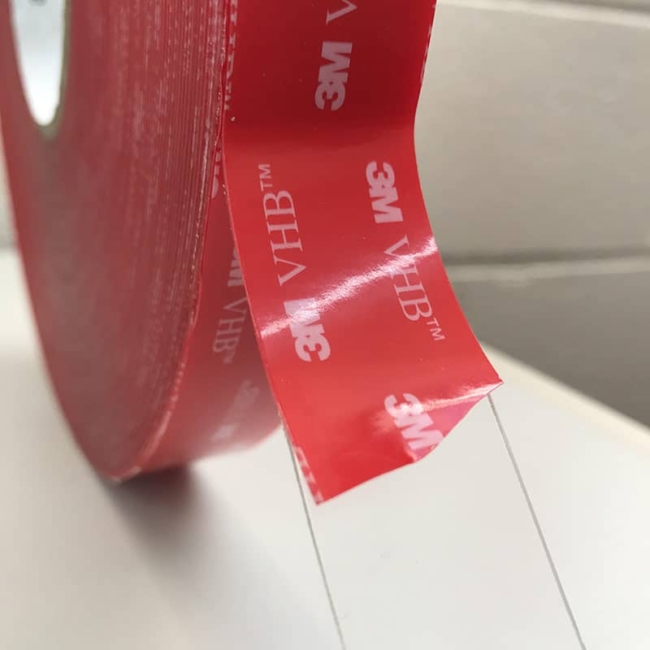

VHB Tape

Adhesive Tape Manufacturer

Advanced Seals & Gaskets offer a range of self-adhesive tapes much of which we manufacture as rolls in-house using our state of the art hot melt adhesive coating machine. These adhesives can be purchased in full rolls, slit coils cut to width or laminated to any of our sponge, rubber, cork, plastic or foam products. Our adhesive tape rolls come in many variations including acrylic, scrim, hi-tack, low tack and perm-peel, each designed to suit the end-users individual application and levels of adhesion strength – from holding insulation seals permanently in situ to temporary signage, we have a solution.

What is an Adhesive Tape Roll?

Adhesive tape rolls are manufactured using a layer of glue (adhesive) coated onto a release paper or liner, with the option of a carrier, the choice of adhesive and carrier used will depend upon the application and the strength of the adhesion required. We offer a wide array of carriers on our adhesive tapes such as ladder scrim, tissue or film. There is also the option of a transfer tape where the adhesive is coated directly onto the release paper without using a carrier. ASG’s adhesive tape rolls can be made using a choice release liners coated with one of many adhesives in our extensive range including hot melt, acrylic, hi-tack and perm peel.

Why use Adhesive Tape Rolls?

Our adhesive tape rolls are highly effective for laminating two materials together, sealing, mounting or generally attaching items to a surface, taken in roll form allows customers and end-users to cut the rolls down to the required shape or size and allows them to cover large surface areas such as full sheets of material. Adhesive tapes have become a popular alternative to using liquid glues and fastenings such as screws or weldings as they are quicker and cleaner to use. These tapes protect surfaces and materials from damage often caused by mechanical fixings and also a more time-efficient method compared to liquid glues as there is no need to wait for them to dry. Bonds and Joins made using adhesive tapes are also more robust compared to screws or glue, therefore able to withstand impact without movement, vibration or expansion/contraction caused by temperature changes.

Different Types of Adhesive Tapes Available

Advanced seals and Gaskets Ltd have an excellent supply chain and in-house adhesive tape manufacturing facilities meaning there is plenty of choices available, further details on the range are discussed below.

Release liners of siliconised paper onto which the adhesive is coated, its purpose is to protect the glue/carrier during conversion, transportation and handling, then to finally release the glue onto the desired surface. Release liners come in different weights, the choice of which is based upon your application and requirements such as tensile strength, flexibility, dimensional stability and release properties. Our range consists of white 80g, 120g and amber 80g, the 80g is more adaptable in curvature whereas the 120g is slightly more ridged with a firmer hold.

Carriers on adhesive tapes differ based upon your desired application, our popular carriers include film, tissue paper, scrim.

Mesh Scrim– added extra support to adhesives allowing them to be more flexible and easier to bond uneven surfaces.

Tissue tapes – are manufactured using non-woven tissue paper as the carrier, these are lightweight, conformable and provide more stability.

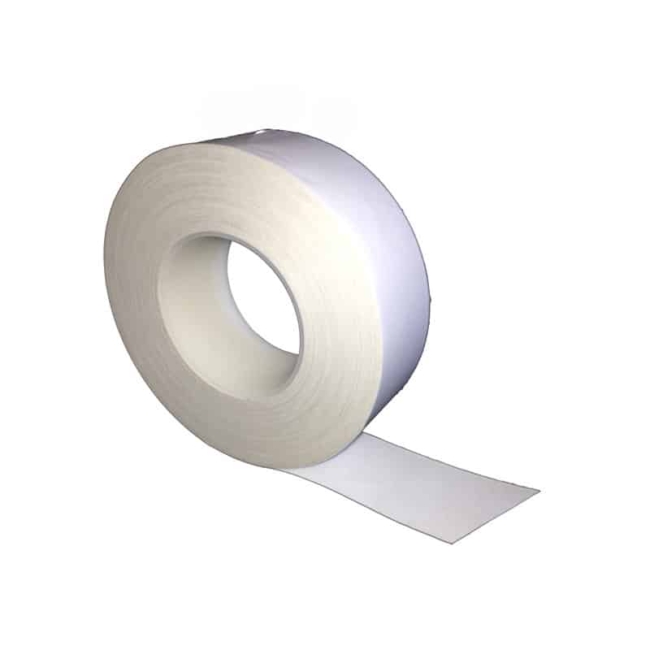

Filmic tapes – usually clear or white, with a high adhesive coat weight ideal for bonding to smooth surfaces such as glass, metal and plastics.

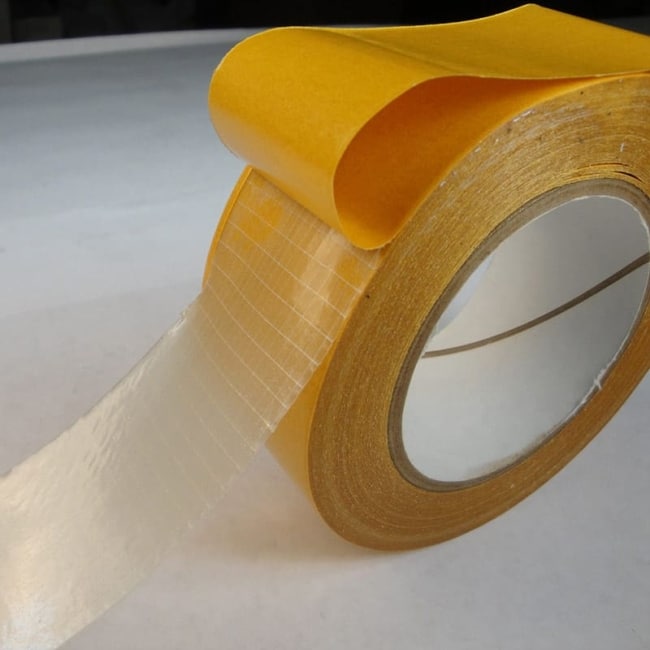

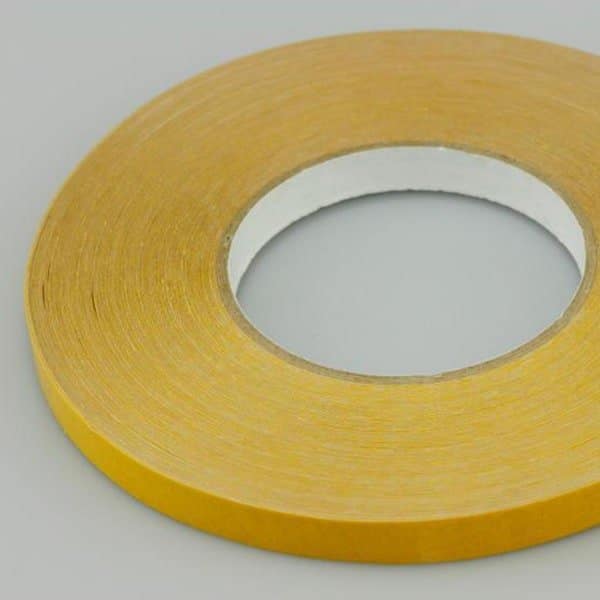

Transfer Tapes – do not use a carrier, the adhesive is coated directly onto the release liner and ideal for use for high initial tack is required.

The final layer on the adhesive tape is the adhesive or glue itself.

Hot melt adhesives – are mostly made up of 100% solids based on thermoplastic polymer formulations. This means the adhesive is solid at room temperature and activated when heated above the softening level, this liquefies the adhesive ready for application then the adhesive will cool and solidify creating a strong lasting hold. This makes hot melt adhesive ideal for bonded joins that can be thermally adjusted.

Acrylic Adhesives – are used in many industries such as transportation, metalwork, composites and sign manufacturing among others. This is due to the minimal odour of the adhesive mixed with the fast curing rate that acrylic adhesive is known for. The acrylic adhesive has improved adhesion and resistance to impact when applied to plastics and metals.

Perm Peel (low tack) adhesive – is created with permanent adhesive on one side with a removable adhesive on the other side. This is designed using a film carrier for strong and permanent adhesion to a material that needs to be temporally applied and removed for example transportation pads to protect glass, electrical appliances or display boards.

For more information please get in touch with our team.

Benefits of Adhesive Tape Rolls

Advantages to using adhesive tape, in general, include cost and time savings, cleanliness and ease of use. They can be used in a countless number of applications as each type has its own unique properties to suit the environment, material, surface and product shape, for example, a low tack perm-peel tape is designed for temporary use such as glass transportation or displays/signage, it will hold an item in place or provide protection, and once it is no longer required can be easily peeled away leaving no residue behind. A hi-tack or acrylic transfer tape is more suited for more long term bonding or where there will be more movement such as within the automotive, construction and engineering industries, etc. Hot melt adhesive tapes are heated before use giving you time to make slight adjustments to create an excellent fit before it cools to create a permanent hold.