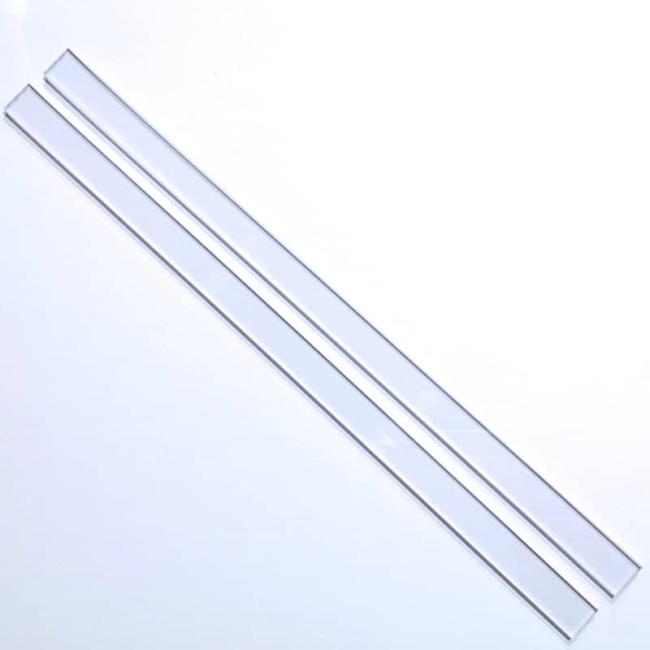

Acrylic Plastic Strip

Product Specification & Key Characteristics

- Colour: translucent, white, red, yellow, green, blue

- Grades: general-purpose, abrasion-resistant, impact-resistant, ESD, Bulletproof

- Finishes: clear, opaque, metallic, mirror

- Tensile Strength: 10,000 PSI

- Max service temperature (in air): 160°F

Full technical data can be supplied upon request,

or downloaded from our online portal.

Acrylic Plastic Strip

At Advanced Seals & Gaskets, our strip production encompasses a variety of materials, including specialized types like cork, sponge, rubber, gasket paper, and numerous plastics. A prominent choice among these is Acrylic Plastic, also known as Polymethyl Methacrylate (PMMA) or colloquially referred to as 'plexiglass.'

Acrylic plastic exists in the form of sheets, offering standard sizes, thicknesses, and an array of colors. From these sheets, strips are meticulously cut to size. In instances where longer or custom-sized strips are necessary, we employ extrusion methods to meet specific orders.

The creation of acrylic plastic strips takes place within our facilities. Working closely with our customers, we utilize their drawings and measurements to ensure precise specifications are met. Depending on size and volume requirements, we employ numerous presses and CNC machines, capable of producing one-off samples or extensive batch runs.

Our comprehensive in-house conversion capabilities enable us to transform sheets into functional strips, available with a plain finish or coated with a selection of self-adhesives.

What are Acrylic Plastic Strip?

Acrylic plastic, a thermoplastic material, becomes pliable when heated to a specific temperature and solidifies upon cooling. Its inherent strength, flexibility, and complete transparency make it a favored substitute for glass, providing similar visual qualities while boasting superior resistance to breakage.

Widely employed in the manufacture of strips and seals, acrylic plastic offers a lightweight yet robust alternative to metals, ensuring durability and protection against weathering and corrosion. These acrylic plastic strips serve various purposes, functioning as gaskets to form seals between uneven surfaces and fill irregularities. Additionally, they play a pivotal role in constructing point-of-display stands, food display units, brochure holders, helmet visors, and an array of other applications.

Product Enquiry

For information on Acrylic Plastic Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Why use Acrylic Plastic Strip?

Acrylic plastic strips are ideal when transparency is needed without requiring high impact resistance, making them a lightweight alternative to glass. These strips are widely used in the production of various items such as buttons, motorcycle helmet visors, viewing ports, display stands, signage, and even for crafting eye lenses and other medical devices.

The manufacturing of acrylic plastic strips can be accomplished using diverse techniques, including extrusion, laser cutting, die-cutting, sawing, and thermoforming, which involves heating the material to reshape it and then cooling and hardening it.

These strips are available in plain or self-adhesive backed forms, boasting excellent chemical and weathering properties. They come in various grades with different strength levels, suitable for diverse industries and environments. Notably, acrylic plastic strips maintain their aesthetic integrity over years of exposure to external factors.

Advantages of Using Acrylic Plastic Strip

Acrylic plastic strips provide a multitude of advantages. They are not only cost-effective and lightweight compared to metals and some sponge materials, but also exhibit superior resistance to wear, weathering, and corrosion, avoiding rust issues prevalent in metal gaskets.

Although relatively rigid, plastic strips can be compressed effectively to create tight seals, making them ideal for insulation applications due to their non-conductive nature for heat and electricity. Furthermore, acrylic plastic strips hold FDA approval, ensuring their safety for use in food preparation and production processes, where they are commonly employed in constructing screens and display units.

These materials and products boast exceptional strength and optical clarity, facilitating ease of fabrication and strong adhesive bonding. For further information on leveraging plastic solutions for your specific application needs, please don't hesitate to contact our sales team.

Benefits of using Acrylic Plastic Strip

- Good dimensional stability and resistance to weathering

- Strong, lightweight alternative to glass

- Highly transparent and optically clear

- Easy to fabricate and machine, or extruded to create bespoke sizes

- Easy to bond and will hold most adhesives

Different Grades

Advanced Seals & Gaskets work with a multitude of material manufacturers and suppliers, giving our customers more choice of plastic - our most popular materials being:

Please contact us using the form below or by calling us on +44(0)1384 252555.