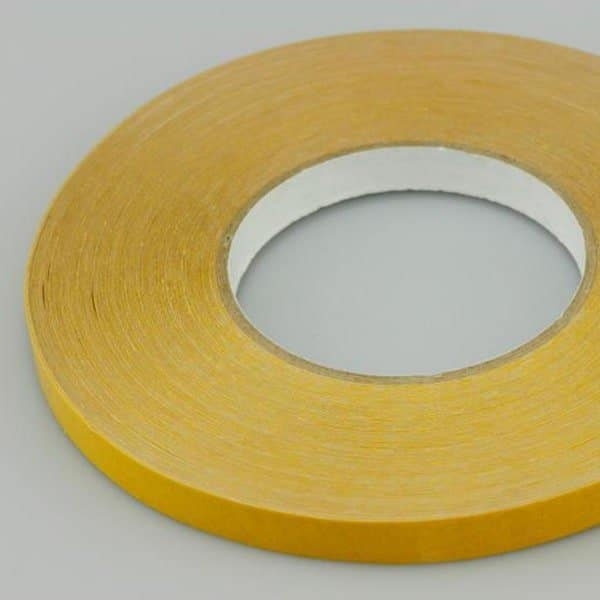

Transfer Adhesive – Precision, Strength & Versatility

Transfer Adhesive is a high-performance bonding solution designed to meet the most demanding industrial and commercial applications. Engineered for exceptional adhesion, flexibility, and clean application, it is the preferred choice for industries ranging from automotive and electronics to manufacturing and construction.

With its reliable bonding capabilities across a wide range of substrates, transfer adhesive ensures secure and lasting connections, making it an essential solution for professional applications.

Key Features of Transfer Adhesive

- Superior Bonding Strength – Adheres reliably to a wide range of materials, including metals, plastics, foams, fabrics, and more, providing a strong, long-lasting bond.

- Clean & Precise Application – Features a liner for easy handling and precise placement, minimising waste and mess.

- Versatile Use – Suitable for lamination, gasketing, mounting, and a wide variety of bonding applications.

- Durable Performance – Resistant to moisture, temperature fluctuations, and UV exposure, maintaining strength over time.

- User-Friendly – Easy to cut, apply, and handle without specialised tools or equipment.

- Custom Solutions – Available in multiple thicknesses, widths, and custom shapes, with tailored formulations for specific project needs.

What Is Transfer Adhesive?

Transfer adhesive is a pressure-sensitive adhesive designed to be applied as a thin, uniform layer onto a substrate or liner. Unlike traditional tapes, the adhesive is transferred directly to the surface, leaving no carrier material behind, which ensures a clean, precise, and professional bond.

This design makes transfer adhesive ideal for applications requiring accuracy, neatness, and flexibility, from industrial production lines to intricate electronic assemblies.

Benefits of Transfer Adhesive

- Precision Bonding – Enables accurate placement for detailed or intricate applications.

- Improved Efficiency – Simplifies the bonding process, reducing time and effort in manufacturing.

- Neat & Professional Finish – Provides a clean appearance, enhancing the overall aesthetics of the product.

- Adaptability Across Surfaces – Bonds effectively to a wide variety of materials, including curved or uneven surfaces.

- Conformability – Flexible and thin, allowing uniform adhesion even on irregular substrates.

Advantages of Using Transfer Adhesive

- Reduced Waste – Leaves no carrier material, minimising excess adhesive and contributing to cost-effectiveness.

- Enhanced Accuracy – Precise adhesive placement improves reliability in sensitive or detailed applications.

- Clean Application Process – Minimises mess and reduces the need for additional cleaning or finishing steps.

- Streamlined Production – Facilitates faster, more efficient workflows in manufacturing and assembly lines.

- Wide-Ranging Applications – Ideal for electronics, automotive components, medical devices, laminating, mounting, and more.

Why Choose Transfer Adhesive?

- Precision Application: Ideal for projects that demand accurate and fine-detail bonding.

- Easy Handling: The liner-backed structure allows for effortless positioning and application.

- Versatility: Adapts to various industries and substrates, including plastics, metals, fabrics, and foams.

- Conformability: Adheres evenly to irregular or curved surfaces for a uniform bond.

- Clean Finish: Leaves no carrier or residue behind, ensuring professional results.

Transfer Adhesive combines strength, adaptability, and precision to deliver reliable bonding in even the most challenging applications.

Call us today at 01384 252555 to discuss your project and discover the perfect transfer adhesive solution.

Please contact us using the form below or by calling us on +44(0)1384 252555.