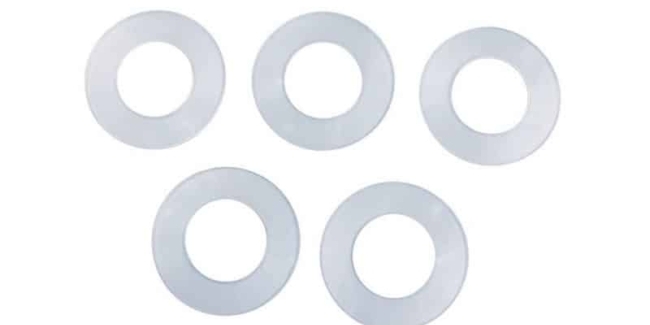

Alveo Foam Washers

One of the most popular material types available from Advanced Seals & Gaskets Ltd is Polyethylene, which comes in numerous grades, densities, and colours. This versatile material can be cut and used to make a wide range of products, including Alveo foam washers. One such type is Expanded Cross-Linked Closed Cell Polyethylene, also sold under the trade names Alveolit® or Alveo.

This physically cross-linked, closed-cell polyethylene foam is available in densities of 33kg, 67kg, and 100kg in continuous roll lengths, with standard thicknesses between 2mm and 10mm. Greater thicknesses can be produced in sheet form, from which washers can be cut. Alveo foam washers are manufactured on-site using drawings or measurements provided by our customers, ensuring the final product meets their exact requirements.

Depending on the size and quantity of washers needed, one of our presses or CNC machines can produce the final product, from one-off samples to multi-thousand batch runs. Each machine is designed to quickly and accurately manufacture perfectly formed washers every time.

What are Alveo Foam Washers?

Alveo is a physically cross-linked, closed-cell polyolefin foam (part of the polyethylene and polypropylene thermoplastics family). It is produced in continuous sheets through a three-stage process: extrusion, crosslinking, and vertical foaming. This is achieved by polymerising ethylene and propylene using oil and natural gas.

Alveo polyethylene is available in a range of densities, in black (anthracite) or white, and can be easily split or laminated to offer non-standard thicknesses. It can then be cut into various finished parts, including Alveo foam washers.

These washers are flat rings with an outer diameter (OD) and inner diameter (ID), cut from sheet material and placed between two surfaces. They act as spacers, seals, or cushioning between nuts and bolts, helping to distribute pressure evenly when tightened.

Manufacturing Alveo foam washers in-house allows us to supply them in plain or self-adhesive backed finishes and even laminate multiple materials together to create bespoke variations.

Product Enquiry

For information on Alveo Foam Washers please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Black (anthracite) or white

- Cell Structure: Closed Cell

- Available Densities: 33kg, 67kg, 100kg

- Available Thicknesses: 2mm to 10mm (skin on both sides; can be split or laminated for non-standard options)

- Temperature Range: -60℃ to +90℃

- Resistances: Most chemicals, ozone, UV, mildew, and bacterial growth

Complete technical data can be supplied upon request or downloaded from our online portal.

Why Use Alveo Washers?

Alveo polyethylene foam has a fine, regular, closed-cell structure that is soft and flexible, with skin on both faces. Standard thicknesses are available, but the material can easily be split or laminated to create non-standard thicknesses. It can be converted into a variety of products, including Alveo foam washers.

This foam offers low water absorption, excellent vapour permeability, and good resistance to chemicals, ozone, and UV. It is odourless and can be supplied in flame-retardant grades.

Alveo foam washers are commonly used for sealing against dust, air, and moisture; filling gaps between uneven surfaces; reducing noise and vibration; or serving as cushioning between fixtures and fittings. Its soft, compressible nature allows it to fill gaps and deformities, creating an effective seal.

Advantages of Using Alveo Washers

Using Alveo polyethylene to produce Alveo foam washers provides many advantages:

- Highly durable and resistant

- Inert to many chemicals

- Excellent weather resistance

- Excellent insulation properties

- Wide operating temperature range: -80°C to +100°C

These qualities make Alveo foam washers ideal for applications in packaging, protection, and cushioning across automotive, construction, and manufacturing industries.

Alveo polyethylene is supplied in continuous rolls of various widths and thicknesses but can be converted into a wide range of parts such as washers, seals, and components for gap-filling, air and moisture sealing, anti-rattle, vibration, and packaging applications.

Benefits of Using Alveo Polyethylene Foam

- Closed-cell and cross-linked structure makes the material impermeable to air and water.

- Good temperature resistance

- Lightweight and durable

- Odourless

- Inert to many chemicals

- Excellent weather resistance

Different Grades of Polyethylene Available

With a network of manufacturers and suppliers, ASG can offer a full range of polyethylene materials, many of which are stocked for quick turnaround. Popular polyethylene types include:

- Polyethylene (Block Foam)

- Anti-static

- Ethafoam

- EVA Foam

- Flame Retardant

- Chemically Cross-Linked

- Plastazote

- Stratocell

Please contact us using the form below or by calling us on +44(0)1384 252555.