Anti-Static Polyethylene Foam Strips – Protective Solutions for Electronics and Fragile Goods

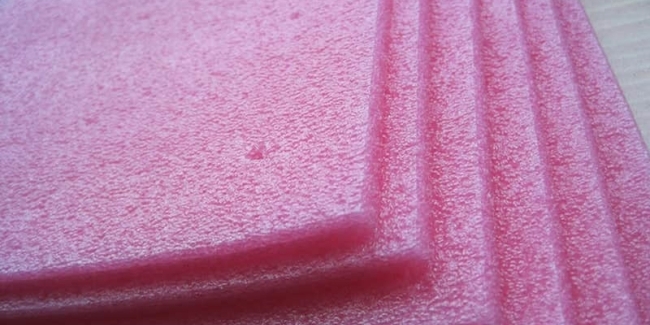

At Advanced Seals & Gaskets Ltd, we manufacture anti-static foam strips designed to protect sensitive equipment, electronic components, and delicate products during storage, transportation, and handling. Our strips are produced from anti-static polyethylene foam, sometimes referred to as Ethafoam, which is easily recognisable by its pink colour and closed-cell structure.

With advanced in-house manufacturing capabilities, including band saws, log cutters, strippers, presses, and CNC machinery, we can produce custom anti-static foam strips in any size, thickness, width, or length. Whether you require coated, laminated, or self-adhesive foam strips, our team can provide precision-cut solutions to meet exact specifications while ensuring high-quality production standards.

Product Enquiry

For information on Anti-Static Foam Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Pink

- Density: 35 kg/m³

- Maximum Operating Temperature: 70°C

- Flammability: Tested to MVSS302

- Resistances: Chemicals, moisture, mould, and fungal growth

- Sheet Size: 2m × 1m

- Thickness Range: Up to 50mm (can be laminated for greater thickness)

- Forms: Rolls, sheets, pre-cut lengths, or continuous coils up to 10m

Full technical datasheets are available upon request or downloadable from our online portal.

What is an Anti-Static Foam Strip?

Anti-static foam strips are polyethylene foam materials combined with anti-static agents to prevent the generation of static electricity. Unlike standard foam, anti-static polyethylene (Ethafoam) prevents damage to static-sensitive electronics such as circuit boards, computer chips, and delicate instrumentation.

These strips are manufactured from rolls or sheets of polyethylene foam, which are cut to size or laminated with other materials to meet a variety of industrial, packaging, and protective applications. The foam’s closed-cell structure ensures it does not absorb moisture, grease, or contaminants, making it ideal for long-term storage and shipping protection.

Applications of Anti-Static Foam Strips

Anti-static foam strips are widely used across multiple industries, including:

- Electronics Packaging: Protecting circuit boards, computer chips, and static-sensitive components during transport and storage

- Medical and Surgical Equipment: Cushioning delicate instruments while preventing static build-up

- Industrial Packaging: Sealing and cushioning fragile items to reduce damage and shipping costs

- Automotive & HVAC: Insulation for glazing, ductwork, or vibration damping

- Custom Case Inserts: Foam can be precision-cut to create bespoke packaging solutions for bespoke items

Anti-static foam strips function like gasket strips, providing a seal between uneven surfaces, filling gaps, and offering cushioning while preventing static accumulation that could damage sensitive products.

Advantages of Using Anti-Static Foam Strips

Choosing pink anti-static polyethylene foam strips provides numerous benefits:

- Prevents Static Damage: Ideal for electronic components and other sensitive items

- High Impact Protection: Absorbs shock and vibration, safeguarding fragile goods

- Closed-Cell Structure: Prevents moisture absorption and inhibits mould or bacterial growth

- Customisable: Can be laminated, coated, or cut into bespoke case inserts for perfect fit

- Lightweight: Reduces transportation costs while providing maximum protection

- Durable & Tear-Resistant: Long-lasting material suitable for repeated use

- Chemical & Grease Resistant: Maintains protective properties in industrial environments

- Flexible & Easy to Use: Can wrap around irregular shapes or cut to size for intricate applications

Why Choose Advanced Seals & Gaskets Ltd?

At ASG, we oversee the entire production process in-house, ensuring every anti-static foam strip meets stringent quality and performance standards. Our state-of-the-art machinery allows us to produce strips for low-volume prototypes or high-volume commercial projects, all tailored to your exact specifications.

Whether used for electronics packaging, industrial cushioning, or automotive insulation, our anti-static polyethylene foam strips combine durability, flexibility, and static protection, providing a cost-effective and reliable solution.

Benefits at a Glance

- Reduces damage and replacement costs

- Provides cushioning for fragile items

- Non-toxic, dust-free, and safe for sensitive applications

- Flexible for wrapping or lining complex shapes

- Can be supplied in rolls, sheets, pre-cut lengths, or laminated forms

- Protects against static, moisture, and chemical exposure

Call Now: 01384 252555

Enquire Now

For more information or to request a bespoke anti-static foam strip solution, complete our enquiry form or contact our team directly.

Please contact us using the form below or by calling us on +44(0)1384 252555.