Anti-Vibration Cork Pads

Anti-Vibration Cork Pads

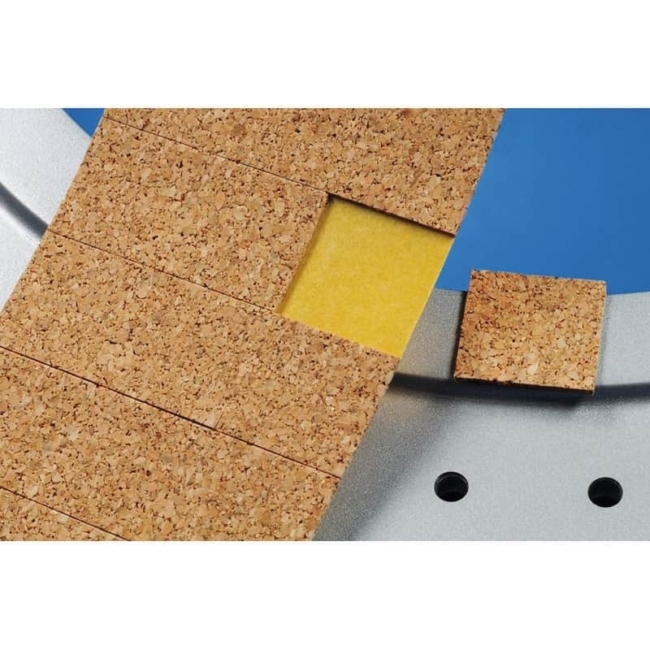

Advanced Seals & Gaskets Ltd stock and supply a variety of cork materials, all of which can be converted into a range of usable products including pads. Cork materials all offer some level of vibration reduction and so when cut down into pad form can be referred to as anti-vibration cork pads.

Our anti-vibration cork pads are produced on-site using drawings or measurements provided by our customers, ensuring the final product is to their exact specification using one of many presses, bandsaws or CNC machines for one-off samples to multiple batches runs.

Depending upon the size and quantity of the cork pad required, they can be supplied as loosely cut parts, or kiss-cut on rolls where a high quantity is required or for use on fast-paced assembly lines, and produced with a choice of finishes.

What are Anti-Viabration Cork Pads?

Anti-vibration cork pads can be cut sheets or rolls, often used in the same way as a gasket, whereby they are used to create a seal between uneven surfaces and fill irregularities. Our pads can be produced as squares or rectangles with the option of radius corners, and also as circular or oval-shaped pads or ‘discs’, in a range of thicknesses.

Manufacturing pads in-house even means we can supply them in a plain or self-adhesive backed finish and even laminate multiple types of material together to create bespoke and unique variations. All cork materials can be used as insulation against vibration, however, cork bonding with synthetic rubber such as EPDM, neoprene, Nitrile or SBR increases the natural corks flexibility and gives it resistance towards oils, petrol, acids and higher temperatures.

Product Enquiry

For information on Anti-Vibration Cork Pads please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: natural with a black speckled effect

- Bonded Material Types: Nitrile, EPDM, SBR or Neoprene

- Resistances: Oils, Sound Suppression, Water Resistance

- Temperature Range: varies between grade

- Thickness: 0.8mm – 25mm Thick (can be laminated for greater thickness)

Full technical data can be supplied upon request,

or downloaded from our online portal.

Why use Anti-Viabration Cork Pads?

Anti-vibration cork pads offer a multitude of solutions including sound absorption, sealing against oil, air or chemical leaks and protection for moving parts within machinery and equipment from abrasive damage.

Anti-vibration cork pads can be found used in and under heavy industrial machinery, railway production, automotive, industrial refrigeration, generators and acoustic suspension buildings where they provide support, stability and help dampen or eliminate the noise and vibrations that are generated from large machinery, these vibrations, if not treated with anti-vibration cork gaskets, can cause damage to building foundations, users hearing and the machine itself which can lead to further dangerous issues.

The Advantages of Using Anti-Viabration Cork Pads

There are many advantages to using anti-vibration pads such as noise and vibration control, thermal insulation, doesn’t absorb water or allow for the growth of mould and is naturally flame retardant. Anti-vibration cork pads are often used for the reduction of noise and vibration produced by heavy machinery or equipment.

The high level of vibration or shaking caused by such machinery not only causes further damage to surrounding foundations and creates an unsafe environment for workers, but can also create excess noise leading to hearing impairment. Cork as a material is safe to work with as it is non-toxic and doesn’t shed like some foams and fibrous materials meaning it will not cause irritations to those with allergies.

Cork pads can be supplied in specifically cut sizes, laminated together to produce non-standard thickness, laminated to other materials for added properties and used in prototyping to cut and manipulate to create the correct functioning pad. For more information about the advantages of cork pads please get in touch.

Benefits of Anti-Viabration Cork Pads

- Sound and vibration dampening

- Thermal insulation properties

- Bonded with other materials for use with different applications

- Oils, chemical, fuel & acid resistance (varies between grades of cork)

- Provides support and stability to reduce excessive movement

- Durable with abrasion and friction resistance

Different Grades of Cork Pads Available

Pads can be manufactured using a range of different cork materials, all of which can offer vibration dampening benefits, but when bonded with rubber, can offer a number of additional properties, these include:

Neoprene bonded cork is suited to sealing at higher temperatures and resistant to weathering and oil. Neoprene Bonded cork is suited to oil, engineering, electrical, anti-vibration and soundproofing applications.

Resin-bonded cork – a lightweight, flexible cork, produced using cork granules bound together using a synthetic resin. This grade of cork is resilient to certain acids and is often used in water retaining applications.

Nitrile bonded cork – manufactured using a combination of cork and nitrile rubber granules, giving a speckled appearance. Gaskets made from this material can be used where oil and fuel resistance is required, or where high-temperature resistance is required, industries include automotive and general engineering.

Natural Cork – consists of grains of cork with no other added chemicals other than a liquid binder known as ‘agglomeration’ to adhere the particles together. Natural Cork is relatively cheap compared to sponge and rubber and can be used as a simple coaster, air/dust/water seals, thermal insulation, acoustic and anti-vibration applications.

Synthetic Cork (SBR) - a combination of synthetic rubber granules and natural cork creates a highly compressible material suitable for low and medium bolt pressure. The rubber used in this grade provides good flexibility and resilience and improved resistance to oil and fuel. This material is often used for automotive and industrial gaskets and within construction or plant rooms for noise and vibration reduction.

Please contact us using the form below or by calling us on +44(0)1384 252555.