Flame Retardant Plastazote Strip

At Advanced Seals & Gaskets Ltd (ASG), we are one of the UK’s leading converters of foam and rubber, specialising in the manufacture of Flame Retardant Plastazote strips. Our Plastazote foam strips are produced in a wide range of densities from 15kg to 70kg — commonly referred to as LD15FR, LD33FR, LD45FR, LD60FR, and LD70FR — to suit a variety of applications and performance requirements.

This closed-cell, cross-linked polyethene (PE) foam is renowned for being lightweight, chemically clean, and flame and heat-resistant, making it an ideal solution for high-sensitivity environments such as aerospace, automotive, medical, and electrical applications.

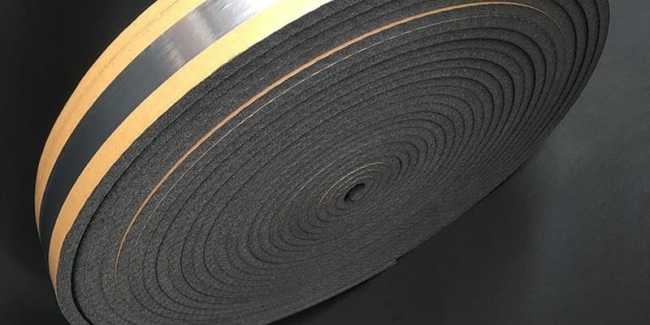

Our Flame Retardant Plastazote PE foam is stocked in block form and converted in-house into custom coils and foam strips. These can be supplied in thicknesses as low as 1.5mm and lengths of up to 100 metres, allowing complete flexibility in design and usage.

At ASG, all flame-retardant Plastazote strips are made to order using advanced cutting machinery — including band saws, log cutters, strippers, and presses — to ensure precision and consistency across every batch. For high-volume production, kiss-cutting options are also available to improve manufacturing efficiency and reduce waste.

Our on-site laminating service allows customers to choose between a plain finish or adhesive-backed options, with the ability to laminate additional materials or foils as required.

Product Enquiry

For information on Flame Retardant Plastazote Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Plastazote Foam

- Colours: Black and white as standard

- Density: 15kg – 70kg

- Cell Structure: Closed-cell

- Temperature Range: -70°C to +105°C

- Resistances: Oils, solvents, acids, alkalis, heat, and flame

Complete technical data for Flame Retardant Plastazote Strips can be provided on request or downloaded from our online portal.

What Are Flame Retardant Plastazote Foam Strips?

Flame Retardant Plastazote strips are precision-cut foam components designed to provide sealing, cushioning, and insulation in demanding environments. They can be produced as continuous rolls, coils, or bespoke cut lengths depending on the application.

Manufactured from cross-linked polyethene foam, Flame Retardant Plastazote combines the lightweight resilience of standard Plastazote with flame-retardant additives for enhanced fire safety. Each nitrogen-filled cell acts like a miniature air pocket, allowing the foam to recover its shape even after compression, making it exceptionally durable and reliable in long-term applications.

Thanks to its closed-cell structure, this foam is impermeable to moisture and air, making it ideal for sealing, gasketing, and protection applications across industrial, transport, and construction sectors.

Why Use Flame Retardant Plastazote Foam Strips?

Flame Retardant Plastazote foam strips combine the performance of standard Plastazote with superior flame, heat, and chemical resistance. They are often used as a cost-effective alternative to more expensive materials such as EPDM or Neoprene sponge while maintaining excellent physical and mechanical properties.

Our on-site conversion facilities allow us to cut rolls of Flame Retardant Plastazote into bespoke strip widths from as little as 4mm, in continuous lengths up to 100 metres.

These Plastazote foam strips deliver exceptional compression recovery, shock absorption, and chemical resistance, including protection against oils, acids, solvents, and alkalis. In addition, they are non-toxic, low-odour, and chemically clean, making them suitable for use in medical, food, and scientific applications.

Typical uses include:

- Sealing and gasketing between irregular surfaces

- Noise, vibration, and impact reduction

- Dust, gas, air, and liquid sealing

- Cushioning between components to prevent wear and friction

Benefits Of Using Flame Retardant Plastazote Foam

- Lightweight, durable, and highly resilient

- Excellent shock and impact absorption

- Water-repellent and buoyant

- Resistant to chemicals, oils, acids, and solvents

- Provides strong thermal insulation

- Non-toxic and low odour

- Excellent flame and heat resistance

Different Grades of Polyethylene Foam

Through our extensive supply network, ASG offers a comprehensive range of polyethylene foam materials, available from stock for quick turnaround. Popular options include:

- Polyethylene (Block Foam)

- Anti-static PE Foam

- Ethafoam

- EVA Foam

- Flame Retardant Polyethylene Foam

- Chemically Cross-Linked Polyethylene Foam

- Low Density (LD) Plastazote (15kg – 70kg)

- High Density (HD) Plastazote (30kg – 130kg)

- Stratocell Foam

Benefits Of Using Flame Retardant Plastazote Foam

Flame Retardant Plastazote foam is a preferred material for seal and strip production due to its balance of strength, flexibility, and thermal stability. Manufactured in-house, ASG can provide custom sizes and finishes tailored to individual customer specifications.

This man-made, closed-cell foam is non-toxic, odourless, lightweight, and weatherproof, with resistance to UV light, heat, and flame. Its impermeable surface makes it easy to clean and maintain, even in outdoor or industrial environments.

Offering outstanding vibration damping, heat insulation, and fire resistance, Flame Retardant Plastazote strips are widely used across the automotive, construction, aerospace, and marine sectors. They deliver long-lasting performance and superior protection in demanding applications.

Please contact us using the form below or by calling us on +44(0)1384 252555.