High Temperature EPDM Sponge Gaskets

Advanced Seals & Gaskets Ltd supply a range of EPDM sponge materials, in various densities, grades and in various different products cut from the material. One of the EPDM sponge grades we can offer is a High-Temperature EPDM sponge. Our High-Temperature EPDM sponge is manufactured at continuous lengths in various standard thicknesses from 3mm to 32mm, with a skin finish on both faces, from which high-temperature EPDM sponge rubber gaskets can be cut.

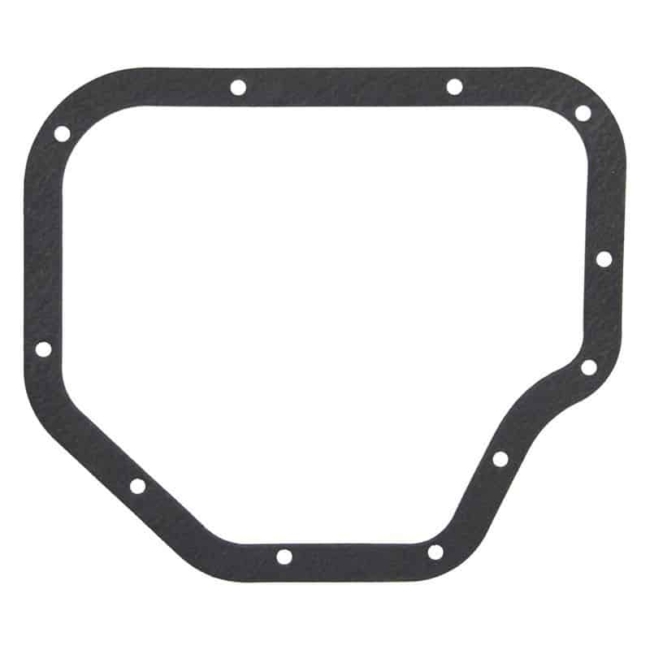

Our high-temperature EPDM sponge rubber gaskets are produced on-site using drawings, samples or measurements provided by our customers, from a simple picture frame gasket to more complex shapes with cut-outs, notches or bolt-holes. Whether it’s a one-off sample or a multi-thousand batch run, we have a machine designed to quickly and accurately produce perfectly formed high-temperature EPDM sponge rubber gaskets every time.

High-temperature EPDM Sponge gaskets can be supplied in a plain finish, split down or laminated in layers to create other non-standard thicknesses, laminated to other materials or coated with a choice of self-adhesives and foils prior to the gaskets being cut.

What are High Temperature EPDM Sponge Rubber Gaskets?

EPDM is an abbreviation of Ethylene Propylene Diene Monomer which are the chemical components used to manufacture this sponge, this HIgh-Temperature variant is a very flexible, closed-cell elastomeric (rubber-like properties of a polymer) insulation material, which has many of the properties of a standard EPDM sponge, but formulated to withstand higher temperature applications up to 150°c.

The closed-cell structure of High-Temperature EPDM sponge means the high-temperature EPDM sponge rubber gaskets can be used in sealing applications, taking the form of a strip or pad but are generally an intricately cut shaped piece of material placed between two surfaces to create a low-pressure seal preventing the leakage of liquids or gas and to seal against the intrusion of dust and debris.

Product Enquiry

For information on High Temperature EPDM Sponge Gaskets please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Black

- Temperature Range: -50°c to +150°c

- Density: 55kg - 70 kg/m3

- Resistances: UV, ozone, weathering, saltwater, grease, many chemicals, mould, fungus, rot

- Flammability Tests: Class 1 resistance to flame spread in accordance with BS 476 Part 7 test procedure - Self-extinguishing, does not drip or spread flames

Full technical data can be supplied upon request,

or downloaded from our online portal.

Help and guidance

If you would like to speak to a representative to discuss your specific application or requirements please call our sales office direct on 01384 469100, alternatively you can send an E-mail. Simply click on the link and forward us your details along with your question and we will contact you immediately.

Samples - Technical High Temperature EPDM Sponge Gaskets

Samples can be submitted for testing upon request.

Call now for sample requests or further help.

Why use High Temperature EPDM Sponge Rubber Gaskets?

High-temperature EPDM sponge rubber gaskets are suitable for applications that require ozone, UV and weathering resistance, combined with the ability to withstand high temperatures.

High-temperature EPDM sponge rubber gaskets can operate between a temperature range of -50°c to +150°c, remaining flexible and still providing an adequate seal at very high or low temperatures.

High-Temperature EPDM sponge rubber gaskets are non-porous, non-fibrous, resists mould and fungus growth and is highly moisture resistant, preventing condensation and corrosion.

The Benefits of using High Temperature EPDM Sponge Rubber

- Temperature range of -50°c to +150°c

- Excellent ozone, weathering and UV light resistance

- High-temperature EPDM sponge rubber gaskets have excellent thermal conductivity

- Excellent insulation properties

- can be manufactured in either plain or self-adhesive backed

- preventing condensation and corrosion

- High-temperature EPDM sponge rubber gaskets have a closed-cell structure prevents bacteria and moulds build-up

The Advantages of using High Temperature EPDM Sponge Rubber Gaskets

High-Temperature EPDM material can be supplied in thicknesses between 3mm and 32mm and manufactured in roll format 1 metre wide a skin finish on one or both sides dependent upon thickness required. As we carry out our conversion onsite, we can split or laminate these materials to create thinner or greater non-standard thicknesses to order which can be used for gasket cutting.

As well as the temperature range, high-temperature EPDM sponge rubber gaskets have many excellent mechanical characteristics including thermal and insulation properties. High-temperature EPDM sponge rubber gaskets offer moisture-resistant properties which prevent condensation, corrosion and the growth of bacteria, rot and fungus.

This material has some resistance to many chemicals, solvents, grease and saltwater, combined with a temperature resistance of 150°C making the gaskets ideal for many demanding applications and industries including HVAC, Refrigeration, Pipeline, Automotive, Solar panels, Steam, White goods and Building & construction, etc.

Grades of EPDM Sponge Available

ASG stock a variety of other grades and densities of EPDM sponge which can call be used to manufacture gaskets each suited to individual applications. These include firm grade, high temperature and semi-open cell varieties:

Medium Density EPDM is available in black or white colour options. EPDM sponge is a strong, synthetic material that has a closed-cell structure making it an ideal material for internal and external sealing applications where minimal compression is required for the material to work as an effective seal. Medium-density EPDM sponge has a density of 90 – 140kg/m3, an operating temperature range of -20°c to +85°c and is flammability tested to FMVSS 302.

Semi-Open cell EPDM combines the flexibility of an open cell material with the excellent sealing capabilities of closed-cell types once compressed. Semi-open cell EPDM pads will allow for the ingress of air, dust, moisture until compressed by 80% of their thickness, following this the product becomes water and airtight and behaves as a closed-cell product.

Firm Grade EPDM Foam is a more resilient material that will not compress as much as the standard grades under load, also this material benefits from increased tear strength and suits some of the more demanding applications such as Automotive, White Goods, Marine, Defence, Building and Construction, etc

For further information, you can view our online specification sheets or speak to a member of our sales team.

Please contact us using the form below or by calling us on +44(0)1384 252555.