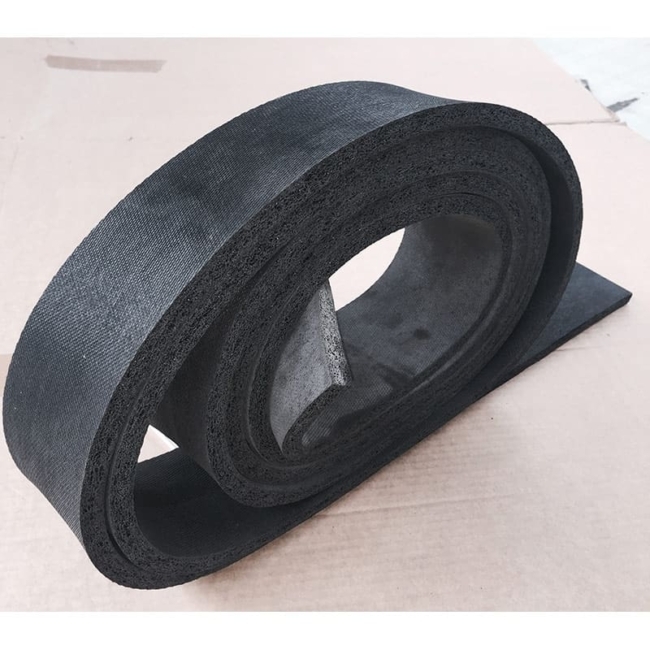

Industrial Sponge Strip

At Advanced Seals & Gaskets Ltd, industrial sponge strips are one of our most popular products. We specialise in a range of sponge materials, including open-cell industrial sponges, also known as Sorbo sponges or open-cell natural industrial sponges. These sponges are produced in rolls of various lengths and standard thicknesses, ranging from 3mm to 25mm, with a skin finish on both faces, allowing industrial sponge strips to be precisely cut.

Following your samples, drawings, or specified dimensions, we manufacture made-to-measure industrial sponge strips using bandsaws, strippers, log cutters, or presses, depending on the required size and quantity. In-house production ensures consistent quality, competitive pricing, and rapid turnaround times.

Strips can be produced as thin as 1.5mm, with widths starting at 4mm and lengths ranging from a few millimetres to 50 meters, depending on thickness. During the conversion process, we can laminate layers for non-standard thicknesses, supply plain strips, or laminate with self-adhesive foils or other materials for specialised applications.

What are Industrial Sponge Strips?

Industrial sponge strips are made from natural rubber sponge with an open-cell structure and patterned skin. This structure provides excellent compression recovery and allows for the controlled circulation of gases and fluids where required.

Open-cell Sorbo sponge strips are typically supplied as cut lengths or continuous rolls/coils, which can be trimmed to size as needed. They are often used in the same way as gaskets, creating a seal between uneven surfaces, filling gaps, and providing anti-vibration and acoustic insulation.

Why use Industrial Sponge Strips?

Industrial sponge strips are ideal for gap filling, sealing, and cushioning applications. They are commonly used to:

- Fill gaps and irregularities between surfaces

- Reduce rattles, noise, and vibrations.

- Seal against air, gas, dust, and liquids.

- Cushion moving parts to reduce friction and prevent damage

The material is soft, compressible, and resilient, providing an airtight protective seal even under repeated compression. Pre-manufactured and stocked in a range of roll lengths and thicknesses, open-cell industrial sponge strips are ready for immediate dispatch or conversion into custom sizes.

The Advantages of Using Industrial Sponge Strip

Industrial sponge strips offer numerous advantages for industrial and commercial applications:

- Soft and flexible with excellent compression recovery

- An open-cell structure allows limited absorption and circulation of gases and fluids.

- Effective for repetitive loading and distortion applications, such as packaging and expansion joint sealing

- Excellent sound and vibration absorption, making them ideal for flooring systems, including joist isolation tapes

- Can be laminated or coated for specialist applications

Benefits of Using Industrial Sponge Rubber

- Excellent compression recovery properties for repeated use

- Conforms to uneven or complex shapes for effective sealing

- An open-cell structure allows limited absorption and fluid circulation.

- Superior anti-vibration properties

- Good weathering and ozone resistance

- Flexible, durable, and cost-effective for a wide range of industrial uses

Other Grades of Sponge Materials Available

In addition to open-cell industrial sponge, Advanced Seals & Gaskets Ltd stocks a variety of other sponge materials suitable for strips, gaskets, and seals:

- EPDM: Medium, firm, semi-open cell, high-temperature grades

- Neoprene: Flame-retardant, medium, and firm grades

- Silicone sponge

- Polyurethane sponge

Please contact us using the form below or by calling us on +44(0)1384 252555.