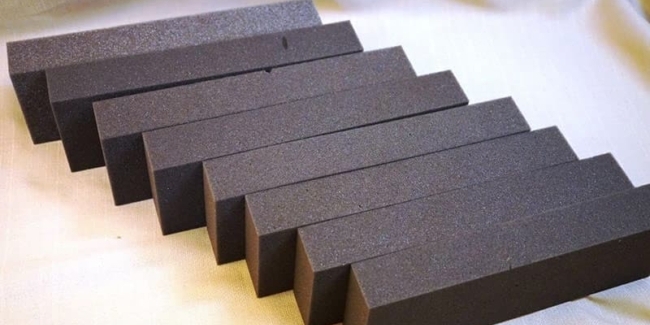

Neoprene / EPDM Sponge Pads

Neoprene / EPDM Sponge Pads

Here at Advanced Seals & Gaskets, we cut and supply pads in a multitude of non-metallic materials, one of which is a neoprene/EPDM blended sponge, used to manufacture our neoprene/EPDM sponge pads. As neoprene/EPDM sponge is one of our core stock materials, pads can be turned around within a minimal lead time using sheets or rolls split directly from the block.

All our neoprene/EPDM sponge pads are cut in house using state of the art machinery and are produced using drawings provided by our customers, giving us the ability to work with them closely and ensure the final product is to their exact specification.

Depending upon the size and quantity of neoprene/EPDM sponge pads required, we have a machine that can manufacture the final product, from one-off samples to multiple batches runs, our expertly trained staff can manufacture neoprene/EPDM sponge pads in thicknesses starting from as 1mm thick, and in plain or self-adhesive backed finish using one of our many presses, kiss-cut machines or CNC oscillating knife.

What are Neoprene/EPDM Sponge Pads?

Neoprene/EPDM sponge is just one of many closed-cell materials on offer from our vast catalogue which we can use to cut neoprene/EPDM sponge pads. Manufactured from a high-quality blend of chemicals - Polychloroprene (Neoprene) and Ethylene Propylene Diene Monomer (EPDM), this combination of the two materials creates a highly versatile product, suitable for applications where a stable, flexible and durable material is required.

Using a selection of in-house machinery ASG can produce square or rectangular neoprene/EPDM sponge pads with the option of radius corners, and also as circular or oval-shaped neoprene/EPDM sponge pads or ‘discs’, in a range of thicknesses. Manufacturing pads in-house means we can offer the option to supply them in a plain or self-adhesive backed finish and even laminate multiple types of material together to create bespoke and unique variations.

Product Enquiry

For information on Neoprene / EPDM Sponge Pads please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Black

- Density: 120 + 20(kg/M³)

- Flammability Testing:FMVSS 302 / UL94 HBF

- Tensile Strength: >500kpa

- Temperature Range: -40ºc to +80ºc

- Thickness: 1mm - 54mm (can be laminated for a greater thickness)

Full technical data can be supplied upon request,

or downloaded from our online portal.

Why use Neoprene/EPDM Sponge Pads?

Our Neoprene/EPDM sponge pads are cut from a high-quality blend of Polychloroprene (Neoprene) and Ethylene Propylene Diene Monomer (EPDM), this combination creates a highly versatile product that offers the benefits of both materials, which are perfect for applications where a stable, flexible and durable material is required.

Neoprene/EPDM blend sponge offers resistance to UV light, ozone exposure and weathering, it closed-cell and non-porous making it air and water-resistant, has excellent ageing properties, good resistance to acid and some resistance to oil. Neoprene/EPDM blend has a wide working temperature range of -40º to + 85º and has flame retardant properties conforming to classification UL94 HF1.

This combination of properties means Neoprene/EPDM sponge pads are suitable for most internal and external applications for example heating & ventilation, white goods, automotive, electrical, sealing, etc

The Advantages of Using Neoprene/EPDM Sponge Pads

There are many advantages to using neoprene/EPDM sponge pads in your project, not only does it have excellent sealing capabilities under compression, its closed cell structure prevents the growth of bacteria and mould, it offers properties such as noise and vibration insulation, UV resistance and good recovery properties, as well as easily holding a number of self-adhesives, foils and other coverings.

Neoprene/EPDM sponge pads have a wide operating temperature range and display mechanical and chemical properties of both materials making them a robust and flexible material that will resist deterioration over time. As this material is stocked in block form, we can split the material down into any desired thickness starting from just 1mm, or laminate layers of material to create a greater depth or composite materials where required.

Neoprene/EPDM blend sponge is easy to convert using a range of methods including bandsaws, presses, oscillating knives and kiss-cut presses, there allowing us to produce pads in just about any size and quantity.

Benefits of Using Neoprene/EPDM Sponge Pads

- Neoprene/EPDM sponge pads is a closed-cell material which prevents bacteria/mould growth

- Air & watertight

- Good weathering, UV & Ozone resistance

- vibration absorption properties

- Neoprene/EPDM sponge pads has a high tensile strength & withstand heavy weight

- Durable

Different Grades of Neoprene Available

Advanced Seals & Gaskets work closely with a number of high-quality material manufacturers and stock a number of grades of neoprene sponge alongside the blended variety, giving our customers more choice, these neoprene variations include medium density, firm and flame retardant grades.

Medium Density Neoprene sponge has a closed-cell structure creating an air, dust and watertight seal, it has excellent ageing properties, being resilient to ozone, sunlight, oxidation and UV exposure and not becoming brittle over time. Neoprene sponge gaskets are resistant to oil, chemically inert, flame retardant and have a wide working temperature range of -40°C to +115°C

Firm Grade Neoprene sponge gaskets are fire resistance tested to FMVSS 302, and have a density of 180kg (+/- 25), meaning they can be used in more heavy-duty applications, where less compression is needed to create a tight seal.

Flame Retardant Neoprene gaskets are grey in colour, can handle continuous temperatures from -40°C to 115°C and subject to more vigorous fire testing ( FMVSS 302, UL94, AFNOR P9750), this makes the material ideal for use within construction and transport applications where a flame-resistant barrier may be required.

Please contact us using the form below or by calling us on +44(0)1384 252555.