Pick And Pluck Foam

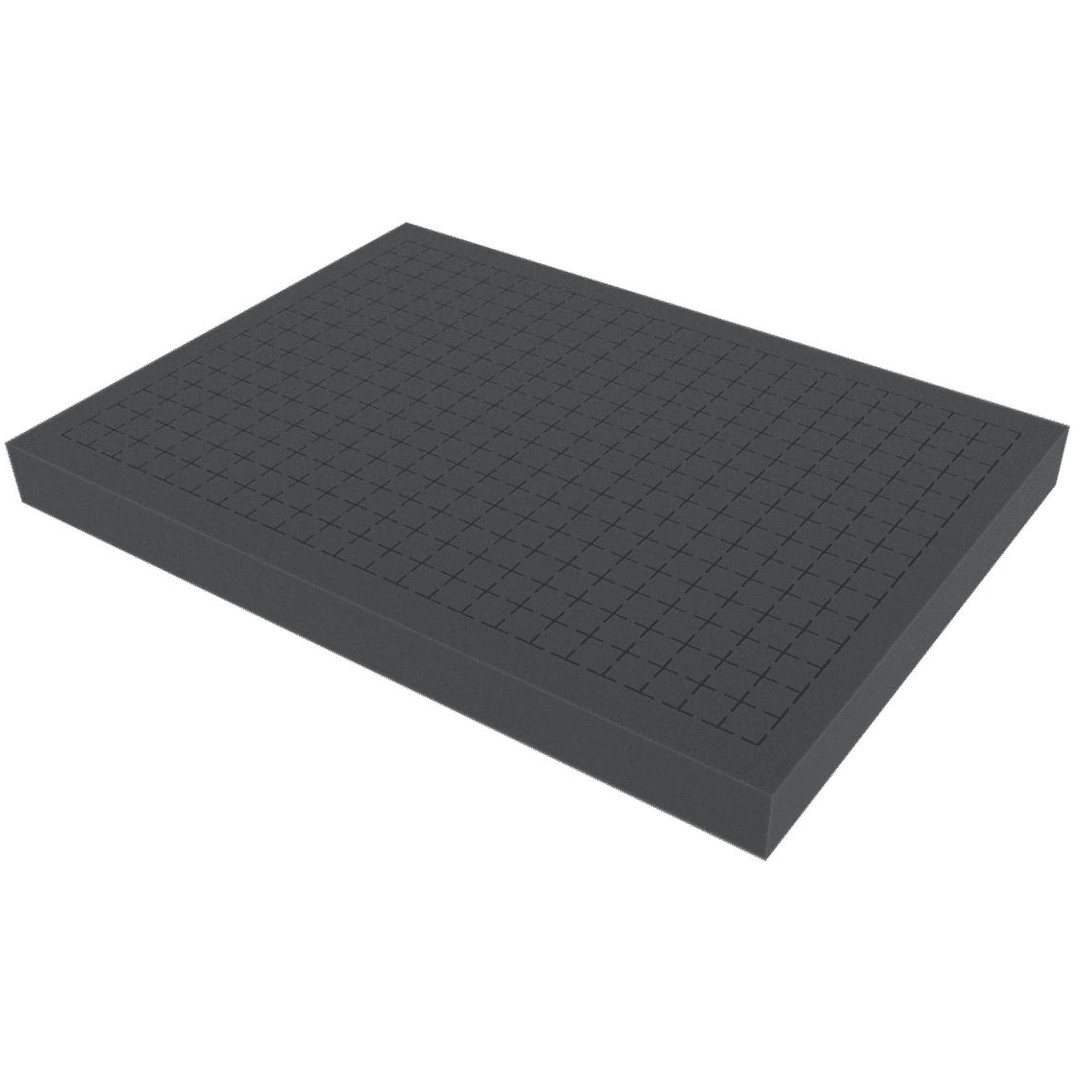

At Advanced Seals & Gaskets Ltd, we offer a comprehensive range of polyurethane foam sheets, stocked and converted to suit various industries and applications. One of our most popular products is Pick and Pluck Foam, recognised for its pre-scored cube pattern that allows for easy customisation.

Pick and pluck foam sheets are available in various thicknesses, including standard options such as 12mm, 25mm, and 50mm, often supplied in multiple layers for enhanced protection. Derived from jumbo master blocks, these sheets can be produced in large sizes such as 2m x 1m or 1m x 1m, or pre-cut into smaller pads suitable for case inserts.

For customers needing bespoke solutions, we offer custom-sized sheets, and our in-house conversion facilities can laminate, cover with foils, or apply self-adhesive surfaces to meet specific requirements.

What is Pick And Pluck Foam

Pick and Pluck Foam Sheets are typically made from polyurethane or polyethylene and serve as protective packaging for delicate or valuable items. The sheets feature a pre-scored cube pattern, allowing users to remove individual cubes and create tailored recesses for objects of various shapes and sizes.

These foam sheets are commonly used for electronics, cameras, tools, firearms, and collectables, providing cushioning and support while preventing movement and potential damage. Available in multiple thicknesses, pick-and-pluck foam ensures a secure, snug fit within cases, boxes, or containers.

Acoustic Eggbox panels

By Aaron Criddle |

Acoustic Soundproofing Panels

By Aaron Criddle |

Acoustic Hexagonal Soundproofing Panels

By Aaron Criddle |

Acoustic Foam Sheet

By Aaron Criddle |

Acoustic Barrier Sheet

By Aaron Criddle |

EggBox Foam Sheets

By Aaron Criddle |

Why Use Pick And Pluck Foam?

Pick and pluck foam is ideal for protective case inserts because it combines softness, shock absorption, and flexibility. Its pre-scored surface allows for easy stacking or layering, enabling the secure accommodation of items with irregular shapes, such as cameras or precision instruments.

Sheets are available in various thicknesses and pluckable square sizes, ranging from 1cm to 1 inch, providing a perfect fit without the need for additional cutting tools. For maximum protection, foam layers can be supplied as a complete set, including a lid, base, and pluckable middle layer, creating a secure sandwich around the items.

Advantages Of Using Pick And Pluck Foam

Pick and pluck foam sheets offer a cost-effective and versatile packaging solution:

- Multi-layer sets with base, lid, and middle layer

- Horizontal and vertical cube removal for custom fit

- Reduces the need for pre-cut or routed inserts, saving tooling costs

- Available in multiple thicknesses and sets for various product sizes

- Provides cushioning, abrasion resistance, and impact protection

This makes the foam ideal for use with tools, medical equipment, high-end cameras, and lighting during transportation.

Benefits Of Using Pick And Pluck Foam

- Economical alternative to custom-cut packaging

- Reduces damage during transit, saving money

- Protects against scratches, vibration, and impacts

- Available in anti-static and flame-retardant grades

- Odourless and non-toxic

Different Types of Packaging Foam Available

While many foams can absorb impact, some are designed with specific protective features:

- Polyurethane (PU) Slabs: Soft, open-cell foam that absorbs shock and recovers quickly, protecting from scuffs and dents.

- Polyethylene (PE): Closed-cell, denser foam ideal for vibration protection and moisture resistance.

- Pick & Pluck Anti-Static: PU and PE foams with anti-static or static dissipative properties, perfect for transporting electronic items.

- Convoluted ‘Eggbox’ PU Foam: Recognisable by peaks and troughs, often supplied in pairs for top and bottom cushioning, and available in Pink Antistatic grade.

Please contact us using the form below or by calling us on +44(0)1384 252555.