Polycarbonate Plastic Pads

Polycarbonate Plastic Pads

Advanced Seals & Gaskets Ltd stock various types of plastics in different grades, colours and thicknesses which can then be used to cut into finished products including pads. One type available is Polycarbonate, Polycarbonate (PC) plastic is part of a group of thermoplastics containing ‘carbonate groups’ in their chemical structure, making them strong and tough materials for use within engineering applications.

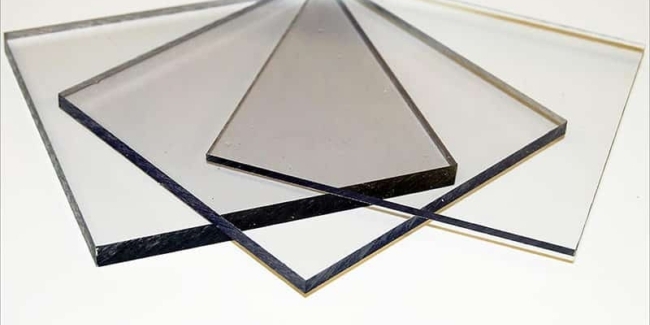

Polycarbonate plastic is visibly clear (transparent), and manufactured in sheet form at thicknesses between 0.7mm to 101mm, in sheet sizes up to 3050mm by 2050mm, from which pads can be cut and supplied in a plain or self adhesive backed finish.

Using one of our many on-site saws, presses or CNC machines, we are able to convert polycarbonate plastic sheets into bespoke sized cut pads, which are produced using customers' drawings or samples as a guide. Non-standard sized pads with different textures and profiles can also be manufactured to order as Polycarbonate plastic can also be moulded or vacuumed formed into bespoke shapes and are found used across several industry sectors.

Product Enquiry

For information on Polycarbonate Plastic Pads please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Polycarbonate Plastic:

- Colours: Transparent - but available in a choice of shades and colours

- Texture: smooth

- Thicknesses: 0.7mm - 101mm

- Temperature Range: -30℃ to 115℃

- Resistances: Good resistance to wear, impact, chemicals, weathering/UV, high temperature

- Flammability: B1 classification (difficult to ignite/ fire-retardant)

Full technical data can be supplied upon request,

or downloaded from our online portal.

What are Polycarbonate Plastic Pads?

Polycarbonate pads are pieces of materials cut into squares or rectangles with the option of radius corners, and also as circular or oval shaped pads or ‘discs’, in a range of thicknesses. Manufacturing Polycarbonate pads in-house means we can supply them in a choice of plain or self adhesive backed finish and even laminate multiple types of material together to create bespoke and unique composite variations. Polycarbonate is a thermoplastic material, meaning it can be melted and reformed repeatedly - with this particular grade benefiting from the addition of carbonate chemicals within the compound creating an extremely strong material, resistant to impact.

Why use Polycarbonate Plastics?

Polycarbonate Plastic pads are so tough, they are often used as a lightweight alternative to glass - offering around 200x more impact resistance!! Polycarbonate plastic materials can be made in a variety of colours, but will remain transparent, a natural feature of this material.

The polycarbonate sheet used in the production of these pads is a tough plastic (shaped into a transparent or opaque sheet) that absorbs little moisture as well as resists chemicals. It is also flame retardant and is not prone to impact damage. Since it has many desirable features, it has been adapted for many uses in place of glass, acrylic, and other materials. As well as strength and excellent impact and chemical resistance, there are an endless number of reasons why Polycarbonate plastic pads are so popular. Polycarbonate plastics are easy to machine into cut pads, flame retardant, lightweight, weather resistant and offer sound proofing properties. Sheets of polycarbonate can be taken in full, for use in solar panel or greenhouse production, or alternatively cut down into [ads for use within electronics, lighting, automotive and aircraft applications.

Other types of plastic Pads Available

Advanced Seals & Gaskets work with a multitude of material manufacturers and suppliers, giving our customers more choice of plastic pad - our most popular materials being:

- PTFE

- PVC

- Nylon

- Polypropylene

- HIPS (High Impact Polystyrene)

- ABS

- Polyester

- Acetal

- Acrylic

- Nylatron

Benefits of using Polycarbonate Plastic pads

- Can be manufactured in a range of transparent colours

- Resistant to chemicals

- Flame retardant

- Impact resistant - up to 200x more than glass

- Weather resistant

- Good machinability

Advantages of Using Polycarbonate Plastic Pads

Using Polycarbonate Plastic pads offers users a number of excellent advantages and thus it can be found in a wide range of industries. The most common use of Polycarbonate plastic pads are within outdoor applications such as glazing, where they can be used in the production of skylights, to construct greenhouse panels,security lighting, bus shelters, etc. Being so strong and impact resistant, they are a popular choice for the production of safety products such as safety goggles and even bullet resistant riot gear. Other uses for Polycarbonate pads includes screens on electronics, spacers within electrical equipment and appliances as a lightweight, non corrosive alternative to metal fixings. Being a thermoplastic material, Polycarbonate plastic pads are reusable, not only can they be melted down and re-formed, they are also highly recyclable.

Please contact us using the form below or by calling us on +44(0)1384 252555.