Polyester Foam Fabrication

Advanced Seals & Gaskets Ltd manufacture various fabricated components produced using Polyester Polyurethane, available in a selection of grade and densities. Polyester Polyurethane foam fabrications are also referred to as Polyester Urethane Foam Fabrications, Ester Based Polyurethane Foam Fabrications and Esterfoam Fabrications.

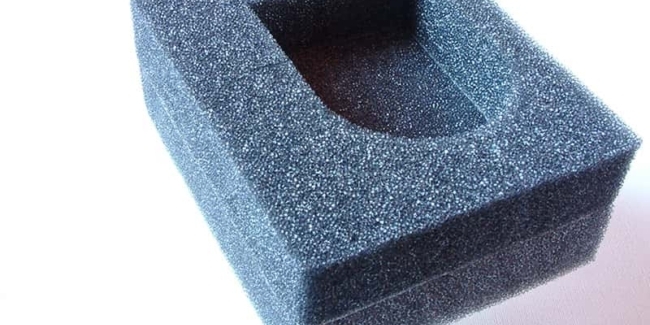

Polyester PU foams are a flexible foam that exhibits high tensile strength and chemical resistance, in comparison to Polyether foam, it is generally more rigid, stronger, and supportive, with physical differences including a glittery sparkle in appearance and feel rougher and denser to the touch. Ester foams used in the production of fabrications are not only manufactured in a standard grade, but can also be manufactured to order in anti-static, conductive electrostatic dissipative (ESD) and Flame Retardant (FR). Ester foam fabrications can be used for packaging applications, however, because of its rough gritty surface texture and chemical instability, an additional material if often required between the foam and the object being packaged.

Polyester Polyurethane foam is manufactured in very large master blocks or ‘buns’ usually ranging from around 2 to 2.5 meters in length, 1 to 2 metres in width and 175 to 1260 mm in thickness, which are held in stock from which we can convert into countless bespoke profiles. A Polyester Foam fabrication requires specialist machinery, usually a selection of saws, drills, buffers and knives. By choosing ASG for your fabrications, you will also benefit from the option using our CNC oscillating knife, which can automatically cut and drill fabricated parts by reading CAD drawings.

Polyester Foam Fabrications are often taken as a cheaper alternative to mouldings and extrusions as there is no initial die/tooling cost for the production of bespoke shapes which are usually required as 1 off prototypes or small quantity runs. All our Polyester Foam fabrications are made to order and are produced using samples or drawings provided by customers, and can take many forms for example multiple material laminating to create composite sheets which are then cut down into gaskets, washers, strip, displays & signage - such as logos/lettering and seals with flexible joints or irregular angles.

Product Enquiry

For information on Polyester Foam Fabrication please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics of Polyester Polyurethane Foam

- Polymer Type: Open cell polyester

- Block Size: (L) 2 to 2.5metres x (W) 1 to 2 metres x (T) 175 to 1260 mm

- Colour: Anthracite/Charcoal grey

- Density: 27-33 kg/m3

- Temperature resistance : -30 to +110 ºC

- Fire resistance: BS4735 self extinguishing FMVSS 302

Thermal conductivity: 0.037 W/m.k

Full technical data can be supplied upon request, or downloaded from our online portal.

What is Polyester Foam Fabrication?

Advanced Seals & Gaskets Ltd have a team dedicated to fabrication construction and the production of one offs and complex products to use during design and prototype development or when singular items are required. Polyester PU Fabrications are often used as a cheaper alternative to mouldings and extrusions as they don’t require any initial set up or tooling cost in order to produce the bespoke shapes.

Fabrications are ideal for use as samples or prototypes prior to paying for expensive tooling for mouldings or extrusions needed for bulk production, they are also perfect for producing props, signs, displays, packaging case/box inserts with routered out shapes to hold specific items in place. The Polyester Polyurethane foams used in these fabrications look very similar to Polyether foams, but are often selected for applications which require a higher level of chemical resistance.

Polyester Foams are more resistance to hydrocarbons, alcohols, stretching and tearing. Polyester Foams have a fine open cell structure which is uniform in appearance and permeable to air and water, whilst giving it a higher viscosity rate, abrasion and cut resistance. Polyester PU foams have a fairly high tensile strength, but not as high as standard polyethylene foams, and have a temperature resistance of -30 to +110 ºC. Polyester Foams Fabrications can be made into components which can be found used in many applications such as filtration, sound and vibration absorption, protective packaging and medical equipment.

Why Use Polyester Foam Fabrication?

Advanced Seals & Gaskets Ltd have a team dedicated to fabrication construction and the production of one offs and complex products to use during design and prototype development or when singular items are required.

Polyester PU Fabrications are often used as a cheaper alternative to mouldings and extrusions as they don’t require any initial set up or tooling cost in order to produce the bespoke shapes. Fabrications are ideal for use as samples or prototypes prior to paying for expensive tooling for mouldings or extrusions needed for bulk production, they are also perfect for producing props, signs, displays, packaging case/box inserts with routered out shapes to hold specific items in place.

The Polyester Polyurethane foams used in these fabrications look very similar to Polyether foams, but are often selected for applications which require a higher level of chemical resistance. Polyester Foams are more resistance to hydrocarbons, alcohols, stretching and tearing.

Polyester Foams have a fine open cell structure which is uniform in appearance and permeable to air and water, whilst giving it a higher viscosity rate, abrasion and cut resistance. Polyester PU foams have a fairly high tensile strength, but not as high as standard polyethylene foams, and have a temperature resistance of -30 to +110 ºC.

Polyester Foams Fabrications can be made into components which can be found used in many applications such as filtration, sound and vibration absorption, protective packaging and medical equipment.

Available grades of Polyurethane

Advanced Seals & Gaskets Ltd work with a number of material manufacturers, giving our customers more choice when looking for polyurethane foams , our most popular grades being:

- Acoustic

- Egg box

- Pick & Pluck

- HLB

- Basotech

- Polyether

- Recon

- Retic

Benefits of using Polyester Polyurethane Foam

- Compressibility

- Cushioning & Insulation

- Light-weight

- Low thermal conductivity

- Low water vapor transmission

- Mildew-resistance

- Sound absorption/Vibration dampening

Advantages of Polyester Polyurethane Foam Fabrication

Like Polyether Foams, Polyester foams and products cut from them are highly durable and offer a range of attractive properties for use in many applications.

The main advantage of Polyester Polyurethane fabricated parts is the cost saving to customers who avoid expensive tooling set ups and minimum order quantities. Being an open cell foam, the Polyester is a breathable material meaning its allows air to circulate throughout its structure, it offers excellent compressibility so will bounce back and recover quickly from repeated loading, this compressibility makes it a great choice of material for cushioning applications.

These Polyester foam fabrications are flexible with a high tensile properties and tear resistance, resistance to mould, mildew and fungus growth as well as grease oil water and temperature with working temperature range of around -30°C to +110°C. Polyester PU foam fabrications can be used in applications where there is contact and exposure to gasses including oxygen, nitrogen and carbon dioxide, its fine cell structure gives the material less flex resulting in a better shock absorbing material.

Polyester Foams can be treated with agents which produce a pink coloured polyester, also known as Pink Anti-static foam which can also be used in fabrication production. The pink foam dissipates electro-static charges in sensitive electronic equipment or instruments keeping them protected during storage and transportation.

Because of Polyester PU foams greater rigidity, they can be made into cleaning products like sponges and mops, some of the other ways in which Polyester Polyurethanes fabrications can be found used include acoustic tiles and soundproofing pads, as protective packaging case inserts and as water or air filters.

Please contact us using the form below or by calling us on +44(0)1384 252555.