PVC Sheet

ASG offers an extensive array of PVC Sheet electrical insulation components, with options derived from diverse plastic sheets. These sheets are available in a wide spectrum of grades, colors, and thicknesses. Notably, this selection encompasses PVC, or Polyvinyl Chloride, renowned as one of the most prominent engineering plastics, with versatile applications in electrical settings.

PVC sheets, a notable inclusion, are obtainable in standardized sizes of up to 2000mm x 1000mm. Their thickness ranges from 1mm to 20mm, ensuring suitability for diverse purposes. These sheets and the resulting components find utility across multiple industry sectors, spanning building, transportation, packaging, electrical and electronic domains, as well as healthcare applications.

Leveraging our comprehensive on-site machinery, which includes saws, presses, and CNC routering machines, we specialize in the transformation of PVC sheets into tailored components. These encompass an array of products such as pads, washers, strips, and gaskets, each customizable to precise requirements. Additionally, the option to supply these components with a choice of adhesive tapes or foils further enhances their functionality and adaptability. Our commitment to offering high-quality, customizable electrical insulation components ensures their relevance and efficacy in diverse industrial applications.

Product Enquiry

For information on PVC Sheet please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics Of PVC Sheet

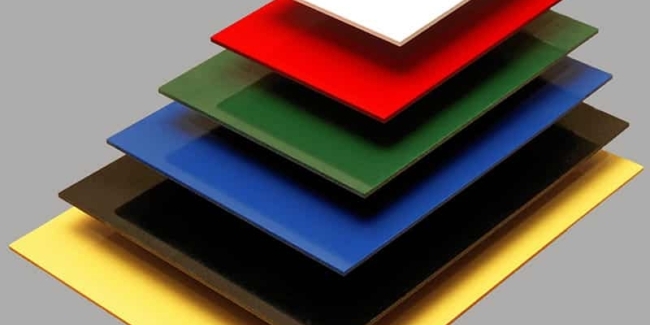

- Colours: black/white/transparent as standard - but others can be made to order

- Finish: opaque, transparent

- Thicknesses: 1mm - 20mm

- Sheet Size: 2m x 1m (standard - can be cut down or produced as moulded profiles)

- Heat Resistance: up to 70° C

- Resistances: Excellent chemical resistance, corrosion, weather resistance, electrically insulating

- Flammability: self extinguishing (when removed from the source)

What are PVC Sheets?

Electrical insulators, like PVC sheet (Polyvinyl Chloride), act as non-conductive barriers, halting the flow of electricity. The versatility of PVC sheets is striking, available in a spectrum of formats, ranging from rigid sheets to ultra-thin, flexible films. PVC, one of the globe's most prevalent synthetic plastic polymers, commands a revered status.

Distinguished by their exceptional durability, PVC sheets are amenable to a myriad of conversion techniques. These include precision cutting, precise milling, precise routering, and pressing, capitalizing on PVC's inherent thermoplastic attributes. This innate property empowers PVC to undergo countless cycles of melting and resolidifying, seamlessly adopting new shapes or forms.

In essence, PVC sheets, bolstered by their non-conductive essence, serve as indispensable electrical insulators. They gracefully endure a multitude of applications and gracefully adapt to varying formats. Their unswerving quality and the ease of processing render them a prized material not only in the domain of electrical insulation but also across a myriad of applications.

Why Use PVC Sheets?

Various electrical insulation sheeting materials are formulated using distinct compounds to confer specific properties. PVC sheets exemplify stability, inertness, and workability, retaining their form even during rigorous milling and sawing processes. Their remarkable chemical stability, coupled with exceptional compressive strength and electrical insulation characteristics, make them an ideal choice. PVC sheets are available in an array of colors, ranging from highly transparent to opaque, catering to various needs. These PVC sheets find extensive utility in the conversion and production of electrical insulation components.

Notably, this electrical insulation material possesses a unique ability to "trap" electrons, rendering them motionless. This electron capture mechanism curtails the buildup of electrical charges, consequently preventing electric shocks. PVC sheets are, therefore, exceptionally well-suited for applications involving circuit boards, wire sleeves, trunking, and high-voltage scenarios, among others, where electrical insulation is paramount.

Benefits Of Using PVC Sheet

- Cost effective

- Impact, corrosion, abrasion and weather resistant

- High chemical resistance

- Strong and rigid

- Can be easily machined, heated and bent, glued and moulded

- low heat and electricity conductivity for use with electrical insulation

Other Types of Electrical Insulation Materials Available

Advanced Seals & Gaskets collaborates with numerous material manufacturers and suppliers, providing our customers with a diverse selection of plastic sheeting. Our most sought-after materials encompass:

Epoxy Glass: This green-hued material offers commendable mechanical strength, chemical resistance, electrical properties, and radiation resistance. It exhibits low moisture absorption and can function effectively within a temperature range of up to +120℃.

Kapton: Comprising polyamide film, Kapton presents a unique blend of mechanical and tear strength, coupled with outstanding chemical, electrical, and thermal properties. It excels in withstanding vibrations and extreme temperatures, making it suitable for demanding environments.

Leatheroid: Also known as Elephantide, this grey/blue paper gasket material serves the electrical industry by insulating hot elements.

MICA: A mineral-based sheeting material known for exceptional mechanical performance, chemical resistance, and electrical and thermal insulation properties. MICA gaskets are often employed as asbestos replacements, capable of withstanding temperatures up to 1000℃.

MYLAR: This highly robust, flexible polyester film boasts dielectric strength, moisture resistance, and superior insulation qualities, rendering it an excellent choice for various applications.

Nomex: Available in the forms of nomex paper or nomex board, it exhibits resilience in high-temperature settings, marked by elevated mechanical and dielectric strength. Nomex proves indispensable for diverse electrical equipment and applications, functioning as a top-tier insulation material.

Advantages Of Using PVC Sheet

PVC sheets and components rank among the world's most widely used materials, owed to their myriad advantages and commendable properties. The material boasts strength, rigidity, and lightweight characteristics. PVC sheets are synonymous with durability and longevity, being inherently resistant to chemical and weather-induced corrosion, shock, and abrasion. Consequently, they find applications across both indoor and outdoor settings.

These PVC sheets are available in standard dimensions or can be custom-molded, offering flexibility. They can be readily transformed through sawing, milling, drilling, gluing, or bending (when heated and manipulated) to yield diverse components, including washers, strips, gaskets, tubes, and pipes.

Notably, PVC sheets exhibit non-toxic attributes and do not conduct electricity, rendering them ideal for electrical applications. Although they are combustible, their high chlorine content renders them self-extinguishing. Employing PVC sheet within electrical devices and equipment serves the pivotal function of safeguarding against the generation and transmission of high voltages. This, in turn, results in energy cost savings, enhanced performance, and ensures user protection from electric shock.

Please contact us using the form below or by calling us on +44(0)1384 252555.