Reticulated Polyurethane Foam Strips

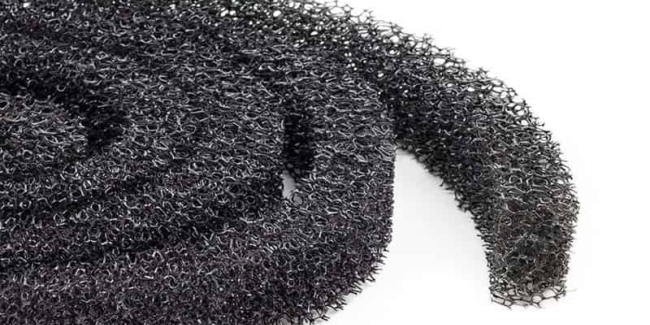

At Advanced Seals & Gaskets Ltd (ASG), we supply high-quality Reticulated Polyurethane (PU) foam strips, expertly manufactured for precision applications across multiple industries. Also known as Retic foam strips, open-cell PU strips, filter foam strips, or skeletal foam strips, these products are highly versatile due to their open-cell structure and are available in multiple porosity grades (10ppi to 100ppi).

Our reticulated PU foam strips are made to order, manufactured in-house using state-of-the-art machinery, including band saws, log cutters, strippers, and presses. For high-volume small strips, we offer a kiss-cut option for faster production and time efficiency. On-site production allows us to ensure consistent quality, precise dimensions, and competitive pricing.

Product Enquiry

For information on Reticulated Polyurethane Foam Strips please complete the following quick enquiry or call us on +44(0)1384 252555.

Key Characteristics of Reticulated Foam Strips

- Standard Sheet Size: 2m x 1m or 1m x 1m

- Density: 25 kg/m³

- Pore Size: 10ppi–80ppi

- Temperature Range: -30°C to +110°C

- Colour: Charcoal grey (marine-safe blue also available)

- Customisable: Can be cut or pressed into bespoke shapes and profiles.

- Properties: UV/light-resistant, resistant to ageing, oil/chemical resistant, reusable Complete technical data can be supplied upon request or downloaded from our online portal.

What Are Reticulated Polyurethane Foam Strips?

Reticulated PU foam strips are made from open-cell polyurethane foam, with a net-like structure that allows air and liquids to pass through while trapping dust and debris. The foam is produced in large blocks or ‘buns’ that are split into sheets before being cut into strips.

- PPI (pores per inch) indicates foam porosity:

- 10–30ppi: Coarse grade with large pores, high airflow, ideal for trapping larger particles.

- 45ppi: Mid-range, balances airflow with finer particle filtration.

- 60–80ppi: Fine pores for slow air/liquid flow and capturing wonderful particles.

Reticulated PU foam strips can be supplied in custom lengths, continuous rolls, or coils, and can be laminated with foils or adhesives on one or both faces if required.

Why Use Reticulated PU Foam Strips?

Reticulated foam strips are ideal for filtration, cushioning, vibration dampening, and air or liquid management. Their performance depends on PPI grade, foam thickness, and compression, all of which affect airflow, filtration efficiency, and dust capture.

Unlike conventional foam strips, Reticulated PU foam strips are predominantly used for:

- Dust and particle filtration

- Anti-vibration solutions

- Sound absorption and noise reduction

- Fluid and air management in industrial, medical, and cosmetic applications

They can also be laminated or coated to enhance functionality.

Available Grades of Reticulated PU Foam Strips

ASG offers a wide range of reticulated PU foam grades to meet different application needs:

- 10–30ppi: Coarse pores, highly compressible, allow maximum airflow, capture larger particles.

- 45ppi: Mid-range, balances airflow with finer particle filtration, moderate compressibility.

- 60–80ppi: Fine pores, slower airflow, effective at capturing fine dust even at lower thicknesses.

- Flame Retardant (FR): Conforms to FMVSS302 for high-safety applications.

Custom colours and bespoke profiles are available to suit specific project requirements.

Benefits of Reticulated PU Foam Strips

- Lightweight and available in multiple porosities

- Low odour and safe for industrial use

- High resistance to mould, mildew, chemicals, and contaminants

- Tear-resistant and compressible

- Washable and reusable

- Excellent vibration and sound-dampening properties

Advantages of Reticulated PU Foam Strips

Reticulated foam strips provide numerous advantages for demanding applications:

- Chemical and fuel resistance – suitable for industrial environments

- The soft, open-cell structure compresses under pressure to adjust airflow and filtration.

- Versatile porosity – choice of PPI ensures effective performance for filtration or cushioning.

- Customisable – can be flame-retardant, coloured, or pressed into a bespoke shape.s

- Applications: Air/water filtration, sound absorption, vibration control, protective packaging, fluid management, and industrial insulation

Their unique net-like structure makes them ideal for industries including food & beverage, medical, marine, industrial machinery, HVAC, and electronics, offering safe, durable, and effective performance in every environment.

Please contact us using the form below or by calling us on +44(0)1384 252555.