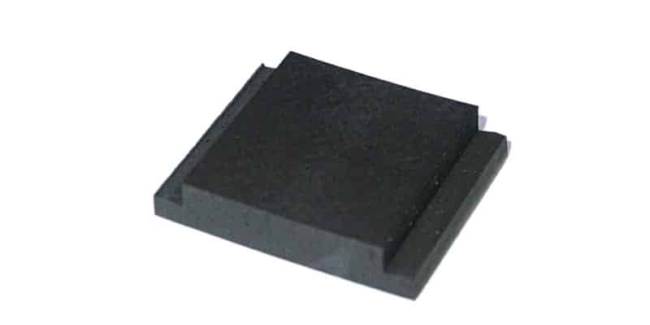

Rubber Fabrication

Fabricated components are just one of the many products converted at our excellent manufacturing facilities here at Advanced Seals & Gaskets, with many various materials fabricated and formed into a range of usable products. One of the many solid rubber materials fabricated by ASG is solid commercial rubber. A fabrication often requires a combination of specialist machinery, usually a selection of saws, drills, buffers and knives, alongside the manual adhesion and construction of the finished product.

By choosing ASG for your solid commercial rubber fabrications, you will also benefit from the availability of our CNC oscillating knife, which can automatically cut and drill fabricated parts by reading CAD drawings. Commercial rubber fabrications are often used as a cheaper alternative to mouldings and extrusions for the production of bespoke shapes as there is no initial die or tooling cost, ideal for when one off prototypes or small quantity runs are needed.

All our solid commercial rubber fabrications are made to order, produced using samples or drawings provided by customers, and can take many forms including multiple material laminating to create composites sheets which can then be cut down into gaskets, washers, strips, displays & signage (such as logos/lettering) and seals with flexible joints or irregular angles.

Product Enquiry

For information on Rubber Fabrication please complete the following quick enquiry or call us on +44(0)1384 252555.

Characteristics Of Solid Commercial Rubber

- Colour: black

- Temperature: -20°C up to +70°C.

- Density: 60-70 shore A

- Resistances: water, oxidation, acids, alkali, gases

- Offers good resistance to abrasion

What Is Solid Commercial Rubber Fabrication?

Fabrications are results of various processes and procedures used to turn solid commercial rubber pieces or sheets of material into custom made 3D usable shapes. Fabrications can be created using a combination of CNC machines, saws, drills, buffers, glues etc, enabling us to create unique products that usually cannot not be produced by one single process for example where the item is too big to be produced in one single piece, or where 3D profiles are required such as cubes or cone shapes.

Solid Commercial (SBR/styrene-butadiene rubber) rubber fabrications are made using an economy grade, synthetic rubber, black in colour, which has a higher wear resistance compared to solid natural rubber and remains flexible even at low temperatures. SBR rubber compounds are often mixed with other polymers such as neoprene (NR/SBR), EPDM and Nitrile (NBR/SBR) which are intended to improve or add additional properties. Solid commercial rubber is available in a range of hardnesses of 60, 65 and 70 shore A.

Why Use Solid Commercial Rubber Fabrications?

Fabrications are often constructed using solid Commercial rubber, as it is offered as a low cost, general purpose material with high tensile and impact strength, resistance to abrasion and flexibility even at low temperatures.

Commercial rubber fabrications are often used as a cheaper alternative to mouldings and extrusions as there is no initial die/tooling cost for production of bespoke shapes, these are ideal for use as samples or prototypes prior to paying for expensive tooling for mouldings or extrusions for bulk production.

They are also perfect for producing props, signs, displays, packaging case/box inserts with routered out cut outs, shaped to hold specific items in place and sleeves.

Benefits of Commercial Rubber

- Excellent resilience and tensile strength

- Excellent seal against air, water and diluted mixtures

- Temperature: -20°C up to +70°C.

- Abrasion resistance

- Excellent impact strength

Grades Of Commercial Rubber Available

Advanced Seals & Gaskets work with many material manufacturers which gives our customers more choice. Commercial rubber is not only available as an SBR grade, but also blended with other polymers to give a cheaper alternative, some of these blends include:

CR/SBR (neoprene) is manufactured using neoprene rubber and SBR compounds to create a material with properties of premium grade material at a reduced cost. This material is generally used for gap sealing and dust seals. Commercial grade neoprene offers resistance to oils, grease, dilute acids and alkalies and are hard wearing enough to be used outdoors.

NBR/SBR (Nitrile) is manufactured using nitrile rubber and SBR compounds to create a material suitable for general purpose gasketing. This commercial grade rubber offers resistance to fuels, petroleum, oils and many solvents making it suitable for use within a variety of industrial applications.

EPDM/SBR rubber is another hybrid made up of 2 different compounds. This particular grade of material offers good resistance to weathering and Ozone deterioration and provides properties such as a high tensile strength and tear resistance. Commercial grade EPDM rubber is typically used for applications such as pipe seals, weather strips and dust seals.

The Advantages of Using Solid Commercial Rubber Fabrications

Commercial or SBR rubber fabrications are very popular amongst a range of industries due the number of excellent properties and the various grades available, making them a very durable and usable range of materials.

Solid commercial rubber has a working temperature range of between 70℃ to -20℃ and has good resistance to abrasion and water, however isn’t suitable for applications involving chemicals, ozone, very strong acids, grease, fat oils and hydrocarbons.

Solid Commercial Rubber fabrications can be made from parts cut from sheets, made up of layers of multiple materials or even from extrusions which are cut and joined together.

As well as fabrications, Commercial rubber can be converted into a range of products such as sleeves, belts, tubes, gaskets and washers for use in countless applications including electrical insulations, engineering applications, window seal, anti-vibration and cable protection, to name a few.

Please contact us using the form below or by calling us on +44(0)1384 252555.