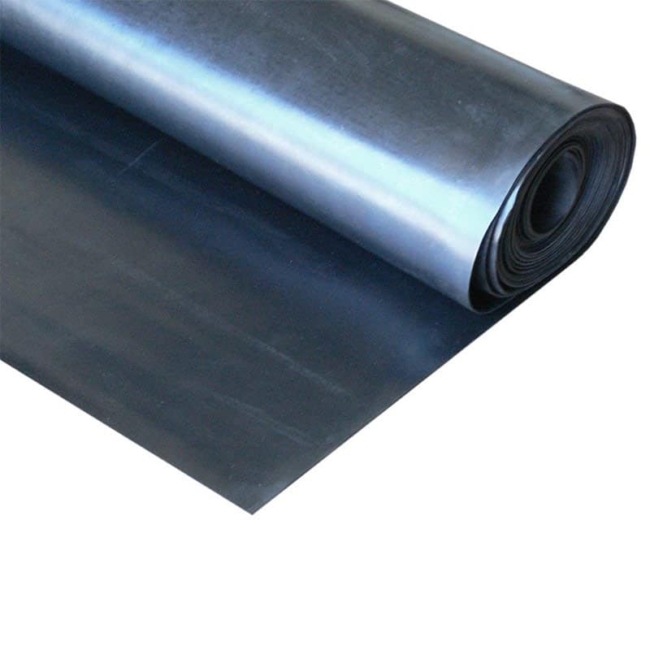

EPDM Rubber Roll

EPDM Rubber Roll

EPDM rubber rolls have been manufactured at ASG’s on-site facilities since 1996 by expertly trained staff producing anything from a 1 off sample roll to hundreds of. Advanced Seals & Gaskets have the ability to manufacture EPDM rubber rolls in thickness ranging from as little as 1mm and in any width up to 1.4meters wide.

We also offer an in-house laminating service allowing us to offer multiple materials to be layered together. EPDM is often purchased in roll form to be later cut into bespoke parts such as sheets, strips, or gaskets and can be found used in applications where water resistance properties are required such as electrical cable jointing and roofing.

What is EPDM?

EPDM is the abbreviated name for Ethylene Propylene Diene Monomer, a synthetic rubber which is such a popular choice as it is air and water tight, ages well without becoming brittle, offers good UV resistance, works well in a wide range of temperatures. EPDM also provides excellent chemical resistance and good electrical properties.

As well as being able to withstand temperatures ranging from a low of -35°C up to a high of 120°C, it provides good general resistance to animal and vegetable oils, chemicals, steam, oxygenated solvents, and electrical properties.

The fact that EPDM is waterproof and works well under pressure makes it the ideal material for use as roofing, deep sea and solar panel applications, while its noise insulating properties mean it is often featured in household appliances that call for lower levels of noise and movement.

Product Enquiry

For information on EPDM Rubber Roll please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Thermal stability – excellent temperature stability –40° to +120°C

- Environmental resilience – EPDM gaskets are extremely resistant to wear, ageing, weather influences, and UV light.

- Chemical resistance – resistance to animal and vegetable oils/good resistance to acids

- Durability – long last lasting quality of an EPDM gasket greatly reduces expenditure on maintenance and replacements

Full technical data can be supplied upon request,

or downloaded from our online portal.

Why use EPDM Rolls?

EPDM rubber rolls can be used to convert into a number of important components for many applications such as sheets, gaskets, washers, sealing strips, etc. EPDM rubber provides excellent cushioning and elasticity making it perfect for use as insulating door seals on refrigeration and freezer appliances, as well as a number of seals, O-rings, and gaskets within the automotive industry where it is used as hosing, air tubes, etc. EPDM rubber rolls are often used for a number of outdoor applications as it has excellent ozone/environmental properties and will also remain stable at both high and low temperatures.

Common outdoor uses of EPDM rubber rolls include roofing and solar panels. Its resistance to abrasions and flex fatigue also makes it a popular choice for belting, bungees, edge guards, and bumpers. This flexible and durable material is an ideal choice in a vast range of industries including aerospace, MOD (Ministry of Defence), food industry, automotive, and construction. ASG supply the full range of EPDM gaskets primarily in black, with the exception of food-grade EPDM which are available in blue and white.

Self-adhesive EPDM roll

Advanced Seals and Gaskets can offer a number of self-adhesive tapes, many of which are manufactured in-house. EPDM rubber rolls can be supplied with a self-adhesive backing, or laminated to other materials using one of our high strength spray adhesives. If you are unsure of which adhesive you require, please gives our sales team a call who will be happy to discuss your options.

The Benefits of EPDM Roll

- Reducing operational noise and shock absorption

- Water-resistant

- Cushioning against abrasion

- Acts as a seal to the link between pipes or connectors

- The resistance and transmission of electricity

- Can be converted into a range of other products

EPDM Rubber Gaskets – FDA Approved, WRAS Approved

Our Food Quality EPDM Rubber rolls are supplied in material blue or white in colour which meets EU1935: 2004, FDA 21 CFR part 177 Section 2600 Allowable Substances. We ensure our FDA Approved EPDM rolls meet stringent quality control, ensuring that the production facility is protected from the risks of contamination.

In addition, we offer WRAS Approved EPDM (The Water Regulation Advisory Scheme) which meets BS EN 681-1 and can be used in applications relating to Drinking and Potable water. This is typically a black EPDM rubber with a cloth finish that has a resistance to Microbiological growth.

Insertion EPDM Rubber combines the properties of EPDM rubber, but with the addition of a textile reinforcement which is embedded within the rubber. The gives the EPDM added mechanical strength and tear resistance often required within the construction and automotive industry.

Grades of EPDM rubber roll

ASG has a vast supply network meaning we have the ability to prove a variety of materials to meet exactly what each client needs and the demands of their application. Our commercial grades of EPDM rubber are available in 40, 50, 60 and 70 shore hardness’s, 40-50 shore rubber offer moderate pliability and elasticity, whilst the harder 60-70 shore offers higher abrasion resistant durability, but less pliability and flexibility.

We also utilise a Water Research Advisory Service (WRAS) Approved EPDM for use in Potable Water Applications, Food Safe Grade (blue or white in colour), and Insertion rubber. Speak to our sales team if you have any questions about the grade you require or would like to see samples.

Please contact us using the form below or by calling us on +44(0)1384 252555.