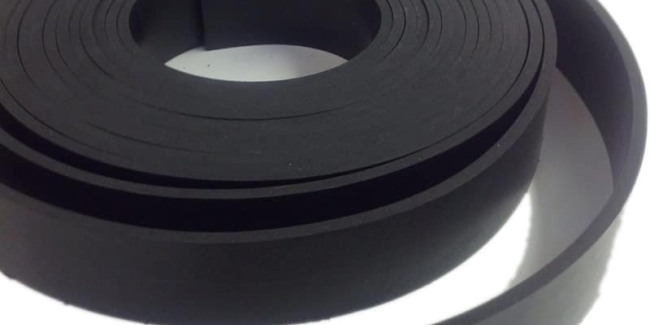

Natural Rubber Strip

At Advanced Seals & Gaskets Ltd (ASG), we supply a wide range of high-quality solid natural rubber products, including natural rubber strips. Manufactured from pure latex from rubber trees, solid natural rubber combines strength, tear resistance, and shock absorption, making it ideal for industrial, automotive, and general sealing applications.

Our natural rubber strips are made to order and produced in-house using band saws, strippers, log cutters, and presses, ensuring complete quality control throughout the manufacturing process. We offer a fully bespoke service, whether producing a single strip or high-volume orders, with the option to supply plain or self-adhesive-backed strips.

Product Enquiry

For information on Natural Rubber Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Key Specifications of Natural Rubber Strips

- Standard Thicknesses: 1mm, 1.5mm, 2mm, 3mm, 5mm, 6mm, 10mm, 12mm

- Standard Sizes: 1.4 meters wide × 10 meters long (1mm–6mm), 1.4 meters × 5 meters long (10mm–12mm)

- Colour Options: Black, White

- Operating Temperature: -30°C to +70°C

- Grades: BS1154 Natural Rubber, Tan Shot Blast Rubber, Abrasion-Resistant Natural Rubber

- Resistances: Abrasion, tear, ozone, water, electrical current

Complete technical data is available on request or can be downloaded from our online portal.

What Are Solid Natural Rubber Strips?

Solid natural rubber strips are cut from sheets or rolls of high-grade natural rubber, providing a durable, flexible, and waterproof material for multiple industrial uses. Strips are often used in the same way as gaskets or sealing strips, placed between two surfaces to provide:

- Leak-proof sealing

- Cushioning and impact absorption

- Anti-vibration and insulation properties

Due to its high tensile strength and abrasion resistance, natural rubber is highly suited for demanding environments where durability and reliability are critical.

Why Use Solid Natural Rubber Strips?

Solid natural rubber strips are highly versatile and widely used in industries that demand strength, durability, and resilience. Typical applications include:

- Conveyor belts and industrial machinery

- Outdoor sealing applications, such as window and door seals

- Automotive components, including pumps, flanges, and hydraulic systems

- General vibration dampening and shock absorption

The abrasion resistance and high tensile strength of natural rubber make these strips ideal for use in high-wear and impact-prone environments.

Different Grades of Solid Natural Rubber Strips

- BS1154 Natural Rubber Strip: High-grade, non-abrasive, high tensile strength. Available in black or white, suitable for food and beverage applications.

- Tan Shot Blast Rubber Strip: Heavy-duty, long-lasting material with excellent abrasion resistance, ideal for scraper blades and chute linings.

- Abrasion-Resistant Natural Rubber Strip: Formulated for high wear and tear environments, with high elasticity and effective sealing under low compression. Available in black, red, or white.

Benefits of Using Natural Rubber Strips

- Strong, durable, and long-lasting

- High impact and shock absorption

- Excellent water and heat resistance

- Provides vibration dampening

- Superior tensile strength

- Available in a variety of hardnesses and thicknesses

- Tear and abrasion-resistant

Advantages of Solid Natural Rubber Strips

Solid natural rubber strips are an ideal choice for industries requiring reliable, versatile, and high-performance sealing solutions. Their durability and resilience make them suitable for applications in:

- Automotive and transportation

- Construction and engineering

- Medical and leisure industries

- Ports, manufacturing, and electronics

With ASG, customers benefit from custom sizes, rapid production, and expert technical guidance, ensuring the right natural rubber strip is supplied for every application.

Please contact us using the form below or by calling us on +44(0)1384 252555.