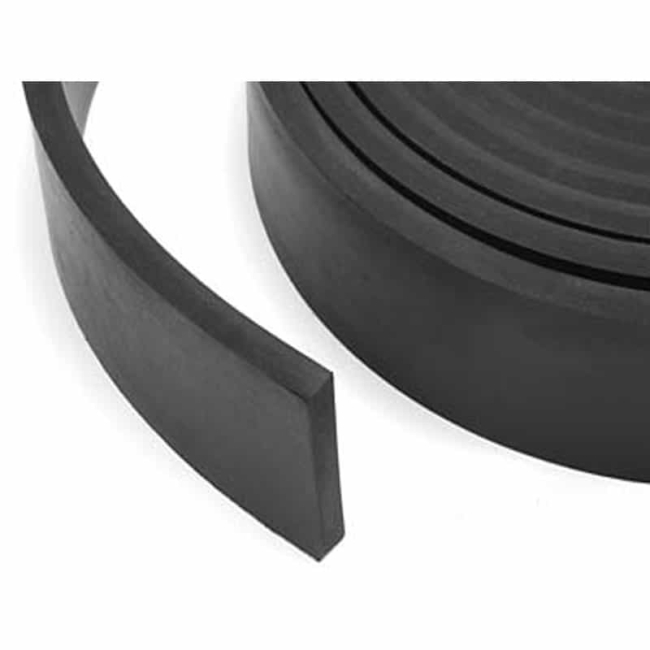

Abrasive Resistant Rubber Strip

At Advanced Seals & Gaskets Ltd (ASG), we manufacture a comprehensive range of high-quality non-metallic rubber strips, including our durable, abrasive-resistant, solid rubber strips. Using the latest state-of-the-art machinery and precision manufacturing techniques, we produce bespoke rubber strips made to order — ensuring superior performance and consistency across every application.

Our abrasion-resistant rubber strips are manufactured in-house using equipment such as band saws, strippers, log cutters, and presses, depending on the required size, quantity, and material type. For small-format, high-volume orders, we also offer a kiss-cutting option for faster turnaround and greater ease of use.

Each strip is cut directly from premium rubber sheets or rolls and can be supplied in thicknesses starting from 1.5mm, in either pre-cut lengths or continuous coils up to 10 metres long. These can be supplied plain, adhesive-coated, or foil-backed, depending on your application needs.

What are Abrasive-Resistant Solid Rubber Strips?

Abrasive-resistant rubber strips are designed to combat material wear and mechanical damage in harsh industrial environments. Abrasion refers to the wear caused when a material comes into contact with another surface, leading to gradual erosion or material loss.

Our abrasion-resistant solid rubber is manufactured from high-grade natural or synthetic rubber compounds, offering exceptional resistance to wear, impact, scraping, and grinding. These robust properties make it ideal for high-stress applications such as lining, sealing, gasketing, and vibration damping.

Solid rubber strips are precision-cut to specific widths and can be supplied in continuous rolls or pre-cut lengths. They are frequently used as seals, protective barriers, anti-vibration pads, or cushioning gaskets, providing long-lasting performance in mechanical and structural applications.

Product Enquiry

For information on Abrasive Resistant Rubber Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

Our abrasion-resistant rubber materials are available in a variety of types, grades, and finishes, each offering distinct mechanical and chemical properties.

Typical characteristics include:

- Colours: Black, white, red, or tan

- Resistance: Abrasion, oil, UV, ozone, and heat (varies by grade)

- Hardness: Available in multiple hardness levels for custom performance

- Temperature Range: Suitable for both high and low extremes, depending on material type

- Thickness Range: Starting from 1.5mm, available in custom widths and lengths

Full technical data sheets can be supplied upon request or downloaded from our online product portal.

Why Use Abrasive-Resistant Solid Rubber Strips?

Abrasive-resistant solid rubber strips are specifically engineered to withstand mechanical wear, erosion, and impact damage. By resisting surface degradation caused by friction, these materials help extend the service life of your equipment, reducing the risk of component failure and costly replacements.

At Advanced Seals & Gaskets, we supply abrasion-resistant rubber in various grades and formulations to suit multiple industrial sectors — from manufacturing and construction to mining, agriculture, and transport.

In addition to wear protection, our abrasion-resistant materials offer secondary benefits such as ozone resistance, weather durability, and chemical stability (depending on the grade). These qualities make them ideal for environments where continuous movement or friction creates conditions for material wear.

Advantages of Using Abrasion-Resistant Rubber Rolls

- Exceptional resistance to wear and tear in harsh environments

- Provides surface protection against impact, scraping, grinding, and corrosion

- Cost-effective, as the long lifespan reduces replacement frequency

- Offers multi-functional benefits, including ozone, weather, UV, oil, and chemical resistance

- Suitable for sealing, anti-vibration, and cushioning applications

- Ideal as protective buffer strips, gaskets, or sealing components within heavy machinery

- Available in multiple material grades and custom thicknesses for specific applications

Different Grades of Abrasive-Resistant Rubber

At ASG, we partner with a trusted network of material manufacturers and suppliers, enabling us to provide customers with a wide selection of abrasion-resistant rubbers, each with unique performance benefits:

Natural Rubber (NR): The most popular option for high-wear environments, natural rubber offers outstanding mechanical strength and flexibility. Typical applications include slurry mixes, silo linings, gaskets, wear pads, and shot blast screening. Available grades include BS1154, red abrasion-resistant rubber, white (FDA-approved) rubber, and tan shotblast rubber.

- Red abrasion-resistant rubber: Tough and durable, ideal for quarry linings, slurry handling, gaskets, and seals.

- White abrasion-resistant rubber: Softer compound suitable for food processing and packaging machinery, offering excellent resistance to ketones, alcohols, and organic acids.

- Tan shotblast rubber (para rubber): Extremely robust and used for chute linings, gaskets, and shot blast cabinets, offering moderate resistance to diluted acids and weak chemicals.

Styrene-Butadiene Rubber (SBR): A synthetic rubber similar to natural rubber, SBR provides excellent abrasion resistance and is widely used for tyres, seals, scraper blades, and buffer pads. It performs best in indoor or protected applications due to moderate resistance to ozone and weathering.

Butyl Rubber: Butyl rubber offers excellent thermal stability, abrasion resistance, and gas impermeability, making it suitable for air retention and tank lining applications. It resists UV and weathering but is not recommended for use with petroleum oils or chlorinated solvents.

EPDM (Ethylene Propylene Diene Monomer)

While EPDM provides moderate abrasion resistance, it is valued for exceptional resistance to ozone, UV, weathering, and heat. Ideal for outdoor sealing, vibration control, and electrical insulation.

Neoprene (Chloroprene): Neoprene rubber combines good abrasion and oil resistance with excellent weather and heat durability. It’s commonly used in marine sealing, outdoor gasketing, and applications involving exposure to seawater.

Nitrile (NBR): Nitrile rubber offers excellent abrasion, oil, and fuel resistance, making it ideal for hydraulic seals, gaskets, and automotive applications. It also provides moderate ozone resistance and strong tear performance.

Hydrogenated Nitrile (HNBR): HNBR combines superior abrasion, oil, and heat resistance with improved fuel and ozone resistance compared to standard Nitrile. Commonly used in tank linings, heavy industrial sealing, and chemical environments.

Contact Us

At Advanced Seals & Gaskets Ltd, we specialise in the design and manufacture of abrasion-resistant rubber strips built to perform under the most challenging conditions. Whether you need a custom-cut strip, a specific rubber grade, or adhesive-backed rolls, we can deliver the perfect solution.

Call us on 01384 252555 or complete our online enquiry form to request a quote or technical advice.

Please contact us using the form below or by calling us on +44(0)1384 252555.