SRBF Strip

SRBF Strip

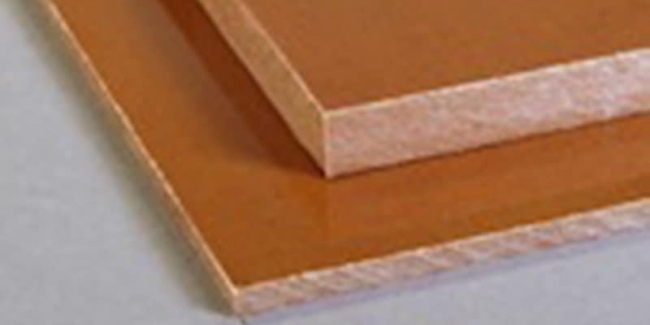

By working with a multitude of suppliers and material manufacturers, Advanced Seals & Gaskets Ltd are able to offer a wide selection of cut strips for use in specialist sealing and gasketing applications. One such group of products offered from our vast catalogue are made using various types of fibre jointing materials, including our SRBF fibre jointing strips; with one type being Synthetic Resin Bonded Fibre, sometimes also called SRBF, Synthetic Resin Bonded Fabrics or fabric based laminates.

SRBF is available in a wide range of thicknesses including 0.8mm, 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm and 20mm with a standard sheet size of 1220mm x 1220mm from which strips can be cut.

SRBF Fibre jointing strips are all made to order, manufactured by our highly skilled workforce, using state of the art machinery including band saws, presses and our CNC Oscillating knife, depending upon the size and quantity required - for very small strips in high volume runs, a kiss-cut option may also be available for faster production and time efficiency for the end user.

In-house production allows us to closely oversee the whole production process to ensure that we consistently produce high quality, competitively priced strips.

Product Enquiry

For information on SRBF fibre jointing strips please complete the following quick enquiry or call us on +44(0)1384 252555.

Key Characteristics of Using SRBF

- Colour: Brown

- Sheet Size: 1220 x 1200

- Available Thicknesses: 0.8mm to 20mm

- Temperature: Up to +115°C continuous

- Standards met: BS EN 60893 Standard: 3-4-PFCC305

BS EN 60893 Standard: 3-4-PFCC203

BS EN 60893 Standard: 3-4-PFCC201

What Are SRBF Fibre Jointing Strips?

SRBF or Synthetic Resin Bonded Fibre is a ‘phenolic’ material, this is made up of layers, in this case using cotton cloth which is placed into a resin or varnish and bound together to create a high strength electrically insulating material.

SRBF fibre jointing strips are pieces of material cut to a specific width and length as requested by our customers, often used in a similar way to a gasket placed between two surfaces to create a seal, provide cushioning or insulation. Most people will instantly choose sponge or rubber when looking for a compressible material for sealing and gasketing applications, however in many cases, a ‘fibre’ based material could also be an option.

Why Use SRBF Fibre Jointing Strips?

Strips converted from sheets are SRBF and are recognised for their excellent wear resistance and electrical insulation properties, SRBF materials are also rigid, lightweight, dimensionally stable therefore making them suitable for low voltage and abrasive applications and can be easily machined into strips for use in in low or medium voltage applications. SRBF sheets can be cut and supplied as finished strips or supplied in full sheets for customers and end users to cut their own parts as and when required.

The Benefits of Using SRBF Fibre Jointing

- Offers enhanced machinability

- Low creep, dimensionally stable, wear resistance, low water absorption

- Excellent electrical insulating properties and chemical resistance

- Operating Temperature up to +115°C continuous

- Resistance to corrosion effects and low moisture resistance

- Multiple grades available

Grades Of SRBF Fibre Jointing Available

SRBF Fine Weave (smooth) - manufactured to meet- BS EN 60893 Standard: 3-4-PFCC305. This smooth grade material offers excellent chemical resistance, electrical insulation and many other mechanical properties, suitable for intricately cut/machined components.

SRBF Fine Weave (coarse) - manufactured to meet BS EN 60893 Standard: 3-4-PFCC203, with every similar properties to the smooth grade but due to the texture isn't suited for intricate machining.

SRBF Medium Weave - manufactured to BS EN 60893 Standard: 3-4-PFCC201, is a great general purpose fabric material, offering high strength, wear resistance and low voltage electrical insulation.

SRBF (commercial) - is a more affordable alternative to the medium weave, manufactured to meet BS EN 60893 Standard: 3-4-PFCC203.

Advantages Of Using SRBF Fibre Jointing Strips

Strips of SRBF or Synthetic Resin Bonded Fibre are often used as they offer users a number of advantages, many of which are similar to those of SRBP, but with better load bearing capabilities in comparison.

SRBF fibre jointing strips are often used in applications where a dimensionally stable, impact resistant and rigid material is required for use in abrasive and low voltage applications. In comparison to plastics, it also offers low creep and corrosive resistant properties.

These sheets of material are available in a range of thicknesses from 0.8mm up to 20mm, all of which can be taken in full or machined into bespoke shaped strips or even as intricately cut components for use as fine toothed gears, seals, geneva wheels, bearings, gears and jigs, etc. and used in wide range of high temperature applications, including in the automotive, electrical, white goods, lighting and energy markets.

Please contact us using the form below or by calling us on +44(0)1384 252555.