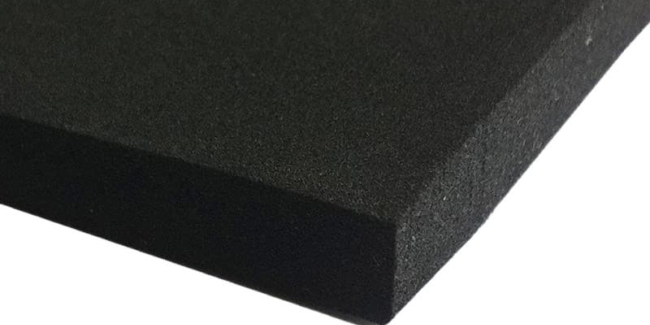

Sulphur Free EPDM Pads

By working with a network of suppliers, ASG are able to manufacture and supply cut pads (such as Sulphur Free EPDM Sponge Rubber Pads) using a range of materials including Ethylene Propylene Diene Monomer or EPDM, which is one of Advanced Seals & Gaskets more popular materials, available in both solid and sponge variants in multiple grades, hardnesses and densities.

One of the more specialist grades of EPDM we can offer is Sulphur Free or Peroxide Cured EPDM sponge, which is manufactured and stocked in block form which can be split and converted into sheets using our state of the art splitting machines, enabling us to cut and supply pads starting from as little as just 1mm thick.

Our Sulphur Free EPDM Sponge pads are produced on-site using drawings or measurements provided by our customers, with whom we work closely to ensure the final product is to their exact specification. Depending upon the size and quantity of pads required, one of many presses, bandsaws or CNC machines can be used to manufacture the final product, from one off samples to thousand off, which can be supplied as loosely cut parts, or kiss-cut on rolls where a high quantity and easy to use product is required or for use on fast paced assembly lines.

Our Sulphur Free EPDM Sponge pads can be supplied in a plain finish, laminated in layers to create greater thicknesses, laminated to other materials or coated with a choice of self-adhesives and foils prior to the pads being cut.

Product Enquiry

For information on Sulphur Free EPDM Pads please complete the following quick enquiry or call us on +44(0)1384 252555.

Key Characteristics of Sulphur Free EPDM Sponge Rubber

- Colour: black

- Density: 120+/- 15 kg/m3

- Sulphur free

- Better resistance to chemicals and oils

- Temperature Range: -30 °C ± 90 °C

- Flammability: FMVSS 302 PASS

- Resistance: Ozone, UV resistance, chemicals

- Impermeable to air and water

Full technical data can be supplied upon request,

or downloaded from our online portal.

Help and guidance

If you would like to speak to a representative to discuss your specific application or requirements please call our sales office direct on 01384 469100, alternatively you can send an E-mail. Simply click on the link and forward us your details along with your question and we will contact you immediately.

Samples - Technical Sulphur Free EPDM Pads

Samples can be submitted for testing upon request.

Call now for sample requests or further help.

What Are Sulphur Free EPDM Sponge Rubber Pads?

Ethylene Propylene Diene Monomer or EPDM sponge materials are usually manufactured as blocks and involve a ‘curing’ process in the production, standard EPDM grades are manufactured using sulphur, however for some delicate applications such as lighting, a sulphur free or peroxide cured material is required as sulphur-cured sponges can corrode materials, such as copper, silver, and other metal components therefore inevitably causing electrical devices to fail.

Sulphur Free EPDM sponge pads are cut from rolls or sheets of material and often utilised in the same way as a gasket, whereby they are used to create a seal between uneven surfaces, fill irregularities or provide cushioning.

Why use Sulphur Free EPDM Sponge Pads?

As ASG manufacture their Sulphur Free EPDM Sponge pads on-site, they can be produced as squares or rectangles with the option of radius corners, and also as circular or oval shaped pads or ‘discs’, in a range of thicknesses. Manufacturing pads in-house even means we can supply them in a plain or self adhesive backed finish and even laminate multiple types of material together to create bespoke and unique variations.

Sulphur Free EPDM is a closed cell material, offering thermal insulation, shock and vibration absorption. Sulphur Free EPDM Sponge pads demonstrate good UV and Ozone resistance and excellent sealing properties against dust, air and moisture, they have a better chemical and temperature resistance compared to standard EPDM and so the components such as these pads are safe for use within lighting, electronics and automotive applications.

The Benefits of Using Sulphur Free EPDM Sponge

- Noise, vibration, shock and reduction

- Naturally compressible to create the perfect air or moisture seal

- Closed cell structure prevents bacteria and mould build up

- Excellent properties making it popular for use in a range of industries and applications

- Easy to convert into a range of products including pads, strips and gaskets, and will hold most adhesives well

- Cost savings on equipment and appliance failure

Grades Of EPDM Sponge Pad Available

EPDM sponge Medium density is air and water tight, ages well without becoming brittle, offers good UV resistance and is able to withstand a wide scale of temperatures ranging from -20°C up to a high of 85°C. It’s excellent electrical insulation material, as well as having good resistance to ketones, ordinary diluted acids and alkalis, Ozone, UV and weathering as well as its general resistance to abrasion. EPDM foam is also flammability tested to meet FMVSS302 and UL94 HBF standards

High Temperature EPDM Foam is closed cell and highly flexible even at low temperatures, with an amazing temperature range of -50°c to +128°c. High-Temperature EPDM foam has many excellent mechanical characteristics including thermal and insulation properties, making this material ideal for many industries and applications including HVAC, Refrigeration, Pipeline, Automotive, White goods and Building & construction, etc.

Semi Open cell EPDM combines the flexibility of an open cell material with the excellent sealing capabilities of closed cell types once compressed. Semi open cell EPDM pads will allow for ingress of air, dust, moisture until compressed by 80% of their thickness, following this the product becomes water and air tight and behaves as a closed cell product.

Firm Grade EPDM Foam is a more resilient material that will not compress as much as the standard grades under load, also this material benefits from increased tear strength and suits some of the more demanding applications such as Automotive, White Goods, Marine, Defence, Building and Construction, etc

For further information you can view our online spec sheets or speak to a member of our sales team.

Advantages Of Using Sulphur Free EPDM Pads

Our customers often choose EPDM for the production of their pads as the material offers a number of advantages with certain grades adapted to meet particular applications.

Sulphur Free EPDM sponge is a closed cell material, offering thermal insulation, shock and vibration absorption, good UV and Ozone resistance and excellent sealing properties against dust, air and moisture, but with an improved chemical and temperature resistance compared to standard EPDM.

Materials cured or vulcanised using sulphur can react with metals such as copper or silver causing corrosion which leads to equipment failure. Sulphur free or peroxide cured EPDM sponge pads are safe for use within lighting, electronics and automotive applications as it will not react with metals it comes into contact with.

As Sulphur Free EPDM is manufactured in blocks, customers are able to order pre-cut products or sheets and rolls of material so they cut their own sheets or bespoke components as the materials can be split or fabricated to order.

Please contact us using the form below or by calling us on +44(0)1384 252555.