Viton Sponge Strip

At Advanced Seals & Gaskets Ltd, we manufacture high-performance Viton Sponge Strips — also known as Viton sealing strips, Viton gasket strips, or Viton isolation strips — designed for durability, flexibility, and exceptional performance in extreme environments. Our skilled in-house team produces custom Viton sponge strips using state-of-the-art machinery to meet precise client specifications and industry standards.

Each Viton strip is made to measure, cut using advanced band saws, log cutters, strippers, or presses, depending on the required size and quantity. Our in-house production process allows us to maintain strict quality control, ensuring every Viton sponge strip we manufacture is consistent, durable, and competitively priced.

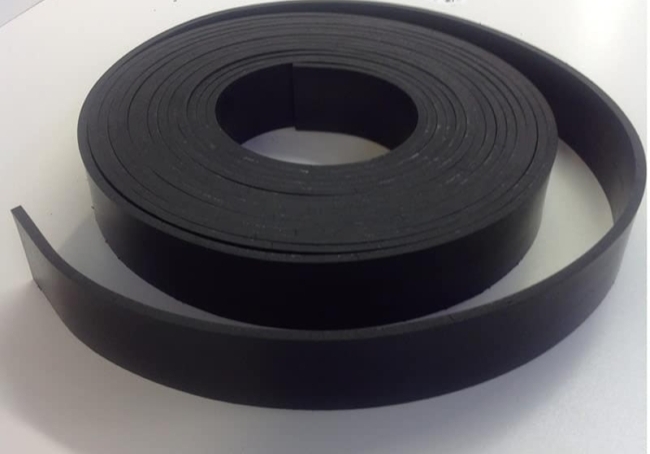

Viton sponge strips are cut from premium-grade rolls or sheets and are available in standard thicknesses starting from 3.18mm. These can be supplied plain, with self-adhesive backing, or laminated to other materials. We can manufacture strips as narrow as 4mm wide, available in pre-cut lengths or continuous coils up to 10 metres long.

What are Viton Sponge Strips?

Viton Sponge Rubber Strips are precision-cut sealing materials designed for demanding environments where high performance is essential. Manufactured from closed-cell Viton sponge rubber, this material combines exceptional durability, chemical resistance, and temperature stability.

Viton sponge is produced in roll form with thicknesses ranging from 3.18mm to 19.05mm and features a skin on both faces to enhance tear resistance. From these sheets or rolls, we cut Viton sponge strips starting at 4mm in width, supplied in either pre-cut sections or continuous rolls up to 10 metres.

Viton sponge is widely used where other polymers, such as EPDM, Neoprene, or Nitrile, cannot withstand harsh conditions. Its robust closed-cell structure prevents air, gas, and fluid ingress, ensuring long-term sealing performance even under high stress or temperature fluctuations.

Product Enquiry

For information on Viton Sponge Strip please complete the following quick enquiry or call us on +44(0)1384 252555.

Product Specification & Key Characteristics

- Colour: Black

- Density: 10 – 19 lb/ft³ (varies by thickness)

- Temperature Range: -20°C to +210°C

- Manufactured Thicknesses: 3.18mm – 19.05mm (can be split or laminated for custom sizes)

- Structure: Closed cell with protective skin on both faces

- Resistance: Chemicals, fuels, oils, ozone, weathering, lubricants, acids, and hydrocarbons

Full technical data sheets are available on request or can be downloaded from our online specification portal.

Why Use Viton Sponge Strips?

Viton Sponge Strips are engineered for superior sealing and insulation in the most demanding industrial conditions. This material is a top choice for applications where heat resistance, chemical stability, and durability are paramount.

Viton sponge offers:

- Exceptional tear resistance thanks to its dual-skin surface

- Temperature range of -20°C to +210°C, suitable for extreme environments

- Chemical, oil, and fuel resistance make it ideal for contact with aggressive substances.

- Outstanding ozone and weather resistance for long-term outdoor use

These qualities make Viton sponge strips ideal for use in:

- Automotive and aerospace sealing (e.g., engine bays, fuel systems, exhaust insulation)

- HVAC and industrial applications requiring vibration dampening and chemical protection

- Construction and engineering projects where exposure to oils, acids, or high heat is expected

Benefits of Viton Sponge Strips

- Superior environmental resistance (ozone, UV, and weathering)

- High chemical and fuel resistance

- Excellent temperature stability (-20°C to +210°C)

- Resistant to oils, lubricants, and acids

- Ideal for sealing, insulation, and vibration control

- Withstands harsh environments and maintains flexibility over time

Advantages of Using Viton Sponge Strips

The closed-cell structure of Viton sponge provides an airtight and watertight seal, preventing the ingress of air, moisture, and fluids — even without the protective skins. The dual-skin finish offers additional tear and puncture resistance, ensuring a longer service life in high-performance applications.

Viton sponge is also highly versatile. It can be split down or laminated to achieve custom thicknesses and cut into precise profiles without tearing or stretching. Available plain or with self-adhesive backing, our Viton sponge strips can be tailored to your exact requirements.

Common Applications Include:

- Automotive and aerospace components

- Industrial sealing and gasketing

- Oil and gas applications

- Vibration isolation and noise reduction

- High-temperature sealing in machinery

At Advanced Seals & Gaskets Ltd, we take pride in manufacturing custom Viton sponge strips that deliver consistent performance, even in the most challenging environments.

Contact our team today on 01384 252555 or submit an online enquiry to discuss your project requirements and request a free quotation.

Please contact us using the form below or by calling us on +44(0)1384 252555.